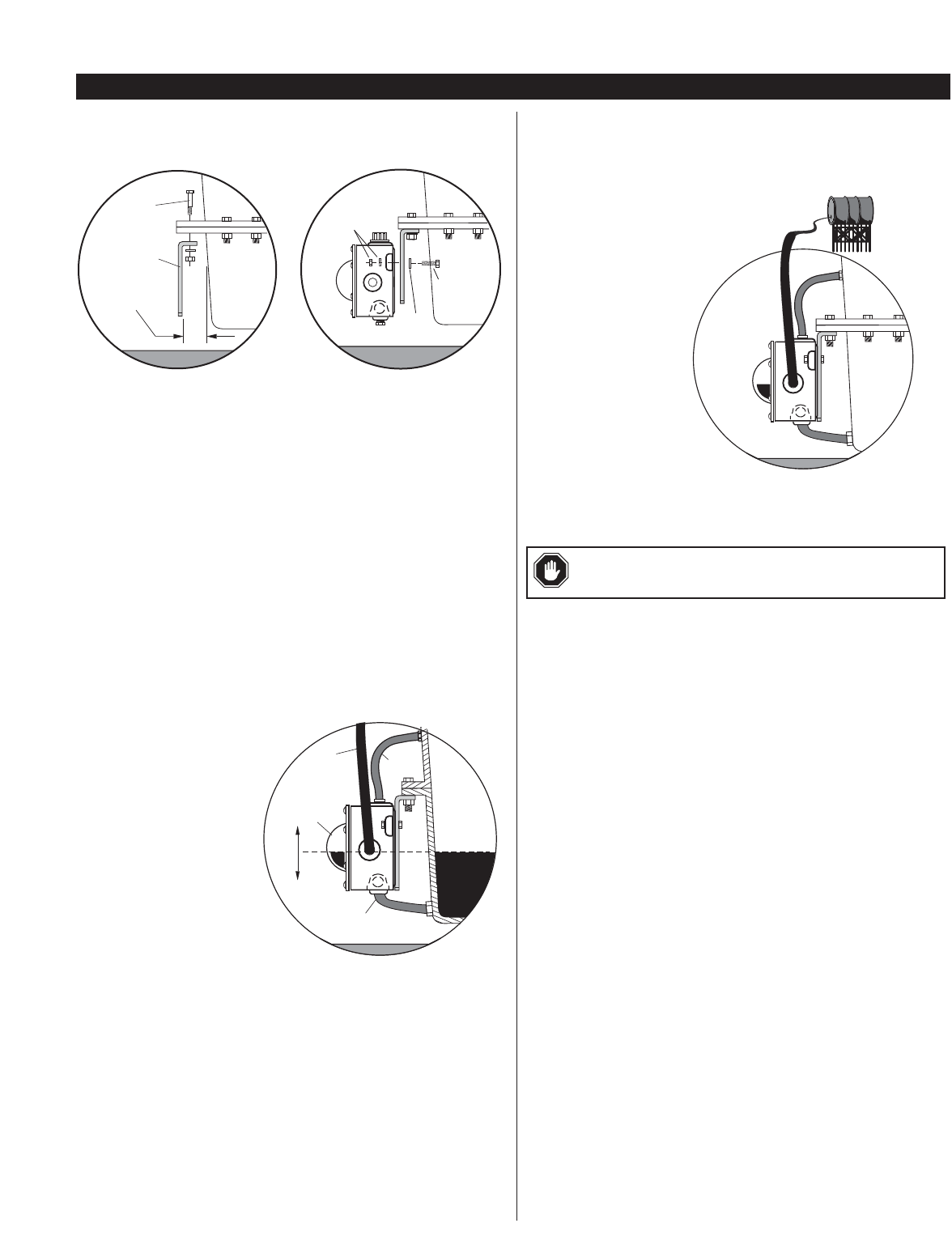

Crankcase (Oil Pan) Mounting

1. Install the universal bracket to the crankcase using the existing crankcase bolts

(Figure 3A). Crankcase bolt diameter must be no larger than 7/16 inch (11 mm).

NOTE: Check clearance between crankcase and mounting bracket

before installing the mounting bracket. If space between the crankcase

and mounting bracket does not allow installation and access to the

adjustment bolts advance to Step 3.

2. Mount the LM2000 to the universal bracket using two 1/4-20 UNC x 1-

1/4 inch bolts, nuts and lock washers supplied. DO NOT tighten the

adjustment bolts too tight. You will have to adjust the LM2000 later in the

installation process.

3. If space between the crankcase and mounting bracket is narrow, install the uni-

versal mounting bracket to the LM2000 before installing to the crankcase oil pan.

Connecting Fittings and Hoses

The following instructions are based on the Murphy optional hose kit

described on page 1. If you did not order the optional hose kit, use the

list designation as a guide to the required materials.

1. Install the LM2000 fittings in their proper locations. NOTE: Apply a

sealant such as Teflon

®

, to all threaded

connections.

2. Attach the 1 inch (25 mm) diam-

eter, flexible monitoring hose

to the crankcase and the mon-

itoring port on the LM2000.

See Figure 4. CAUTION:

The hose must slope slightly

downward from the LM2000

and MUST NOT have any

droops or low spots.

NOTE: If the drain plug on the

crankcase is used for the connection, we

recommend installation of a tee to allow

draining of the crankcase for service.

3. Install the 1/2 inch (13 mm) I.D. x 3 ft. (914 mm) hose to the vent connec-

tion on the LM2000 and to the vent connection on the crankcase. See

Figure 4. The vent connection on the crankcase must be well above

the regulated oil level. All hoses must be clear of obstructions, valleys,

or dips that could create liquid traps, or gas/air pockets. The vent and

crankcase connections should be as straight as possible.

BEFORE CONTINUING, VERIFY THAT ALL HOSE CLAMPS ARE TIGHT.

4. Fill the crankcase to the proper oil level. With the engine running and

warm, loosen the mounting bracket adjustment bolts and adjust the

LM2000 so that the oil level in the sight gauge is aligned with the white

“index line” on the dial (Figure 4). Tighten the adjustment bolts securely.

Connecting the LM2000 to an Oil Supply Tank

1. Remove the plug from the oil inlet connection. Be sure the removable screen,

inside the connection, is clear of debris. Install the oil inlet connection.

2. Connect a 1/2 inch I.D. (13 mm) or larger hose

to the oil inlet fitting on the LM2000 and to the

shutoff valve on the oil supply tank. See

Figure 5. Recommended minimum

height above the LM2000 is 2 ft.

(0.6m); maximum 25 ft.

(7.7m). The hose must

maintain a downward

slope and not have low

spots or droops.

Maximum head pressure

rating is 9.50 psi or 25 ft

oil (head pressure).

3. Before filling the supply

tank with oil, be sure the

tank is clean and dry and

the shutoff valve is closed.

Also, be sure all hoses and clamps are tight. Fill the tank with CLEAN

oil.

4. After oil supply tank is full, open the shutoff valve.

Next, make the proper electrical connections for the application.

(See Snap-switch ratings and schematic on page 1.)

Switch Test

To test the shutdown or alarm functions perform the following:

NOTE: Installations with closed vent systems can only be tested with

the engine off.

1. Unscrew the vent fittings.

2. Using a long narrow shank screw driver, gently insert until contact is

felt with float arm. Gently push the float arm down.

3. Verify proper switch operation

LM-00011N page 3 of 4

TYPICAL INSTALLATION

Figure 3B

Crankcase

Universal

Bracket

Crankcase

Bolt

Note Clearance

before mounting

Adjustment

Bolt

Flat

Washer

Lock washer

and Nut

Figure 3A

Oil Inlet

Hose

Oil Supply

Tank

Figure 5

Viewing

Lens

Monitoring Hose

Crankcase

Oil Level

Running

Engine

Vent

Hose

Oil Inlet

Hose

Figure 4

WARNING: Overfill condition can be caused by excessive

inlet pressure and/or improper “vent to crankcase” installation.