PAGE 48 — MQ SP4030 SAW • OPERATION MANUAL — REV. #0 (01/22/09)

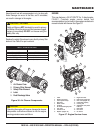

3. Lock down the wheel mount assembly attachment bolts

when the appropriate alignment distance is set.

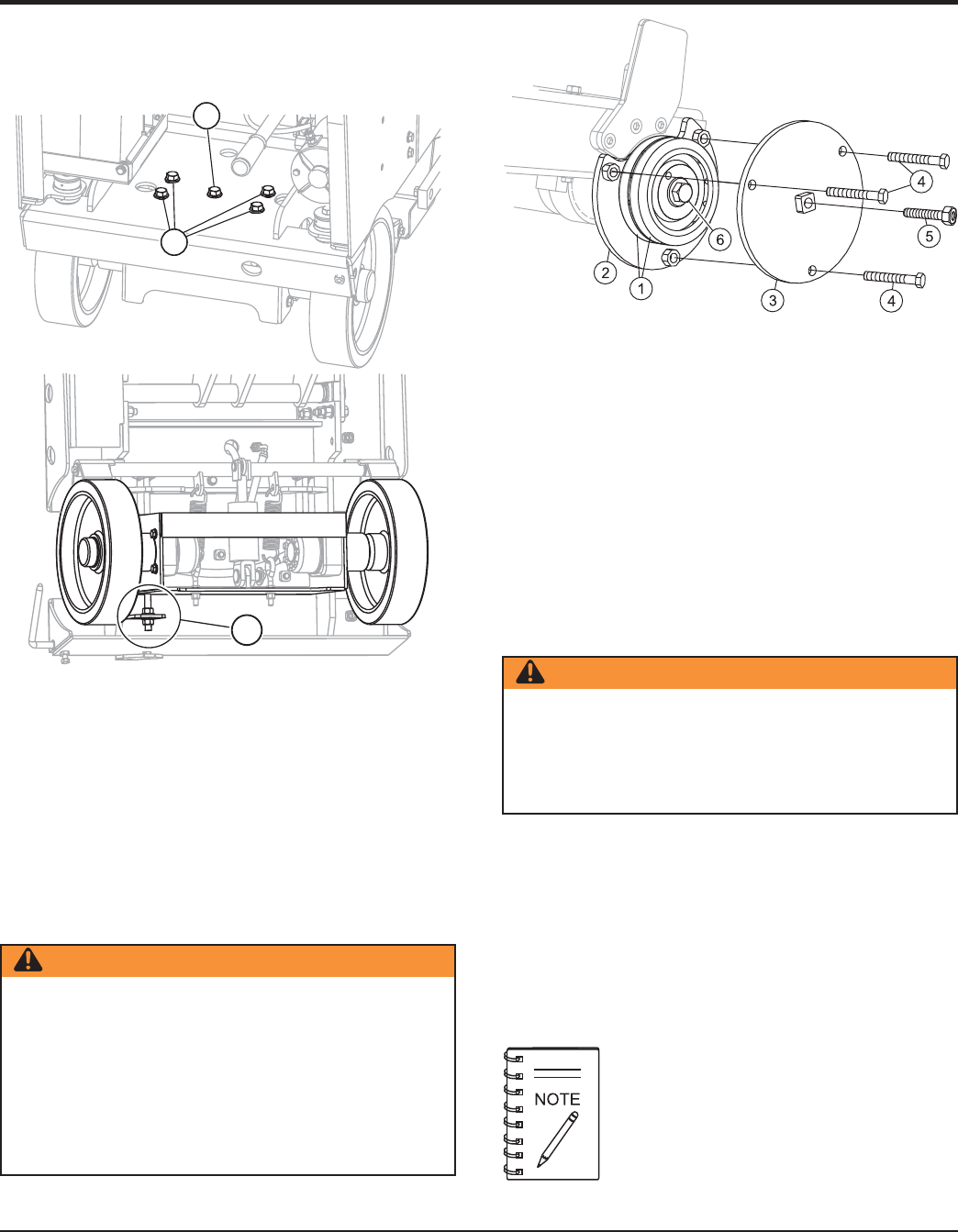

BLADE FLANGE REMOVAL/INSTALLATION

Correct removal or installation of the inner blade flange

requires a flange puller (p/n 18503) as shown in Figure 53.

MAINTENANCE

1

2

3

1. Pivot Attachment Bolt

2. Adjustment Attachment Bolts

3. Adjustment Screw

Figure 52. Drive Wheel Alignment Bolt Locations

WARNING — Outer flange

The outer flange MUST be in place to prevent the puller

assembly and inner flange from flying off when the taper

breaks loose. Injury or equipment damage could

otherwise result.

WARNING

If unfamilar with this operation, seek assistance or

training from someone that is familar with this operation.

Because of the tapered fit between the blade flange

and blade shaft, 5-10 tons of force is required to release

the inner flange from the blade shaft. Both parts and

tools can become dangerous projectiles if instructions

are not followed properly.

Removing the Inner Blade Flange

1. With the outer blade flange in place, remove the blade

mounting bolt (Figure 53, item 6).

2. While the 3 perimeter bolts (item 4) hold the two puller

plates together, slide the horseshoe plate (item 2) of

the flange puller behind the shaft side of the inner

flange.

3. Tighten the center puller bolt (item 5) to remove the

inner flange from the blade shaft.

1. Blade Flange

2. Horseshoe Puller Plate

3. Puller Plate

4. Perimeter Bolt

5. Center Puller Bolt

6. Blade Mounting Bolt

Figure 53. Blade Flange Puller

If the inner flange does not readily break free

from the tapered blade shaft while the center

puller bolt is tightened, lightly tap on the

center puller bolt to allow the flange to break

free from the shaft.