PAGE 14 — QP4TZT10P/TMP16F/TMPXF TRASH PUMP • OPERATION & PARTS MANUAL — REV. #1 (08/29/11)

GENERAL INFORMATION

APPLICATION

The QP4TZ Trash Pump is designed to be used for

dewatering applications. Both the suction and discharge

ports on the trash pump use a 4-inch diameter opening,

which allows it to pump at a rate of approximately 526

gallons/minute (gpm) or 2,000 liters/minute (lpm).

Trash or self-priming pumps are designed to purge air from

the suction line and create a partial vacuum in the pump

body. The reduced atmospheric pressure inside the pump

allows water to flow through the suction line and into the

pump body. The centrifugal force created by the rotating

impeller pressurizes the water and expels it from the pump.

ENGINE

This trash pump is powered by a 9.9 horsepower, air-

cooled, HATZ 1B40 diesel engine.

TRASH PUMP

Trash pumps derive their name from their ability to handle

a greater amount of debris and solids than standard

centrifugal pumps. This pump generally handles solids up

to 1/2 the size of the discharge opening making them less

likely to clog. Also trash pumps are capable of handling

water with 25% solids by weight.

The advantage of using a trash pump is that it can be

quickly and easily disassembled in the field "without tools"

and easily cleaned when clogged.

SUCTION LIFT

This pump is intended to be used for dewatering applications

and is capable of suction lifts up to 25 feet at sea level. For

optimal suction lift performance, keep the suction hose or

line as short as possible. In general, always place the pump

as close to the water as possible.

TRAILER

The QP4TZT10P is equipped with the TRLR10P trailer

(without fuel cell) for basic trailer application.

The QP4TZTMP16F is equipped with the 16-gallon Multi-

Purpose TRLRMP16FP trailer.

The QP4TZTMPXF is equipped with the 28-gallon Multi-

Purpose TRLRMPXFP trailer.

ELEVATION

Higher elevations will effect the performance of the pump.

Due to less atmospheric pressure at higher altitudes,

pumps DO NOT have the priming ability that they have at

sea level. This is due to the “thinner air” or lack of oxygen

at higher altitudes.

A general rule of thumb is that for every 1,000 feet of

elevation above sea level a pump will lose one foot of

priming ability.

For example, in Flagstaff, Arizona where the elevation is

approximately 7,000 feet, the pump would have a suction

lift of 25 feet rather than the 18 feet at sea level. Table 4

shows suction lift at various elevations.

Table 5 shows percentage drops in performance as

elevation increases.

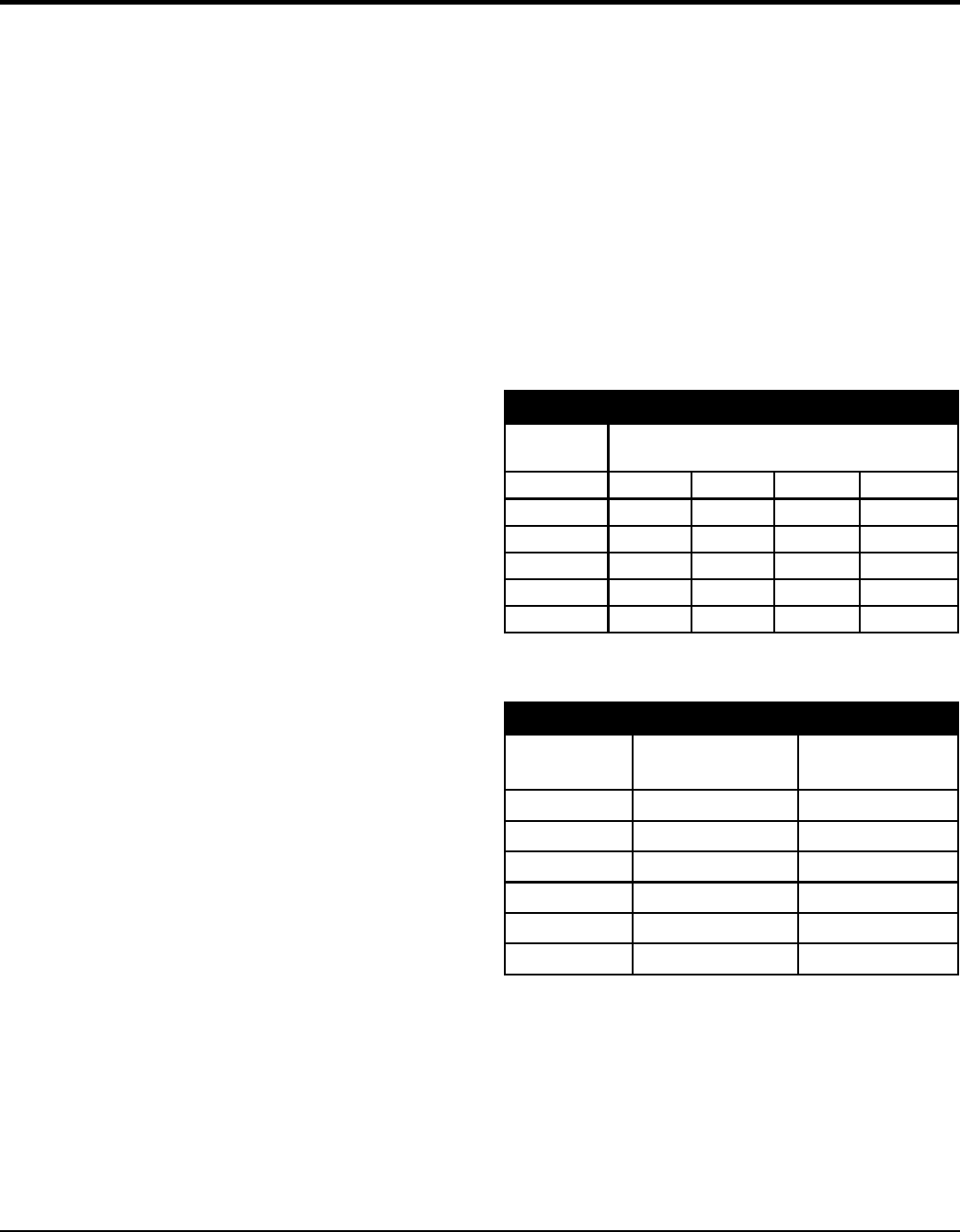

Table 4. Suction Lift at Various Elevations

Altitude

Feet (Meters)

Suction Lift in Feet (Meters)

Sea Level 10.0 (3.048) 15.0 (4.572) 20.0 (6.096) 25.0 (7.620)

2,000 (610) 8.80 (2.680) 13.2 (4.023) 17.6 (5.364) 22.0 (6.705)

4,000 (1,219) 7.80 (2.377) 11.7 (3.566) 15.6 (4.754) 19.5 (5.943)

6,000 (1,829) 6.90 (2.103) 10.4 (3.169) 13.8 (4.206) 17.3 (5.273)

8,000 (2,438) 6.20 (1.889) 9.30 (2.834) 12.4 (3.779) 15.5 (4.724)

10,000 (3,048) 5.70 (1.737) 8.60 (2.621) 11.4 (3.474) 14.3 (4.358)

Table 5. Performance Loss at Various Elevations

Altitude

Feet (Meters)

Discharge Flow Discharge Head

Sea Level 100% 100%

2,000 (610) 97% 95%

4,000 (1,219) 95% 91%

6,000 (1,829) 93% 87%

8,000 (2,438) 91% 83%

10,000 (3,048) 88% 78%