PAGE 28 — MQD2H/3H DIAPHRAGM PUMPS — OPERATION AND PARTS MANUAL — REV. #7 (05/24/13)

)deunitnoC(GNITOOHSELBUORTENIGNE.8ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

yrotcafsitastonnoitarepO

.setautculfdeepslanoitatoR

?reporpmitnemtsujdaronrevoG .reveltcerrocotronrevogtsujdA

?evitcefedgnirpsronrevoG .noitingiecalperronaelC

?citarrewolfleuF .enilleufkcehC

noitcushguorhtninekatriA

?enil

.enilnoitcuskcehC

gnikrowtonretratslioceR

.ylreporp

?trapgnitatornitsuD .ylbmessaretratsliocernaelC

?eruliafgnirpsgnirpS .gnirpslairpsecalpeR

TROUBLESHOOTING

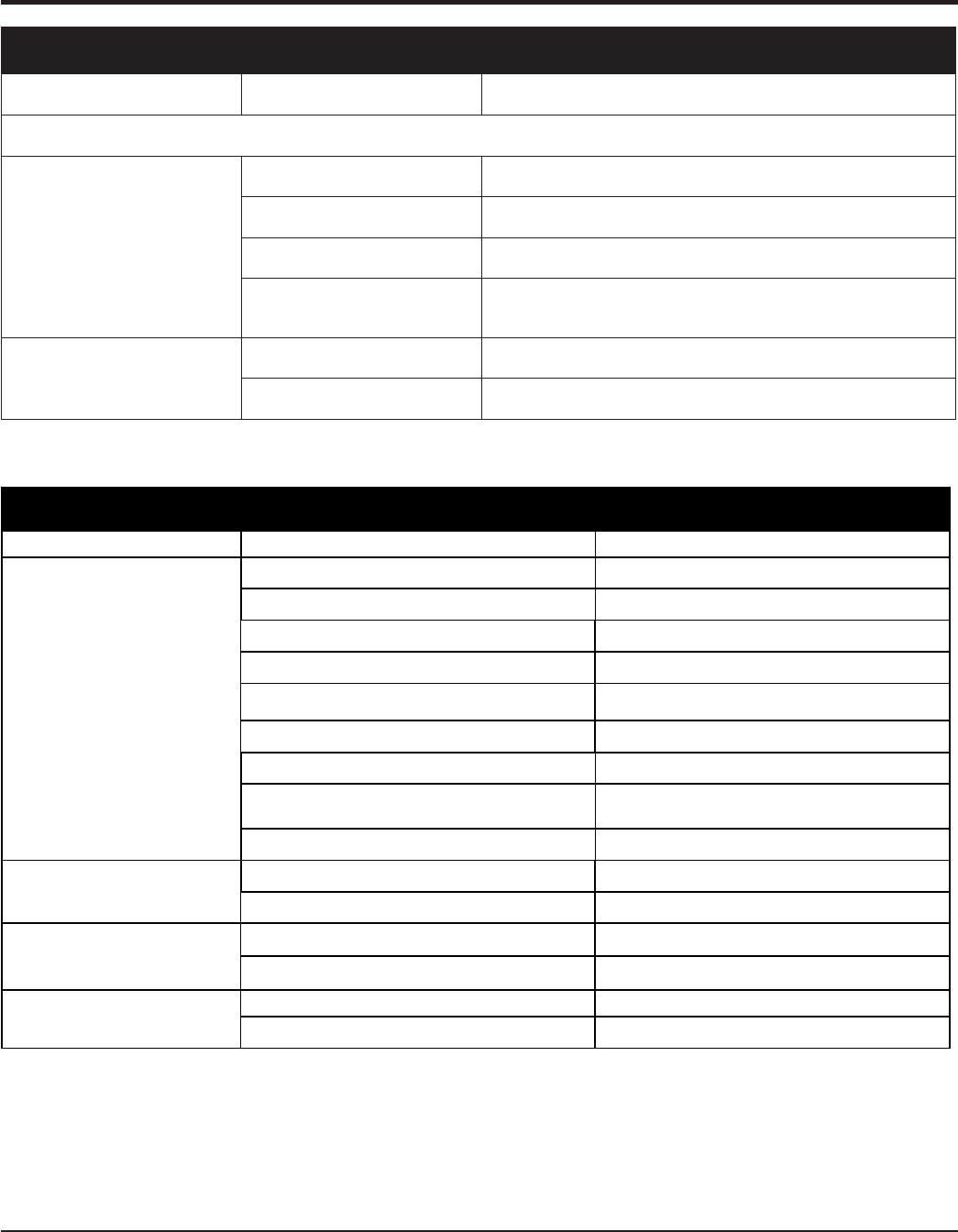

Table 9. Pump Troubleshooting

SYMPTOM POSSIBLE PROBLEM SOLUTION

Pump does not take on water.

Not enough priming water in the housing? Add water to suction chamber.

Engine speed too low? Increase throttle.

Strainner plugged? Clean strainer.

Suction hose damaged? Replace or repair hose, and clamps

Air leak at suction port? Check that fittings are tight and properly sealed.

Pump is located too high above water line? Move pump closer to water.

Debris collecting in pump housing? Clean pump housing.

Valves not seated correctly?

Check that valves are seated correctly. Pour water in

in suction chamber to help seal valves.

Pump does not prime correctly? Check diaphragm for breaks or leaks.

Pump takes in water, little or no

discharge.

Engine speed too low? Increase throttle speed.

Suction hose leaks at inlet. Clean strainer.

Suction hose leaks at inlet.

Teflon Tape/Pipe Dope not used? Apply teflon tape or pipe dope to NPT fittings.

Hose diameter is too large? Use same diameter on suction/discharge ports.

Discharge hose does not stay on

coupling.

Pressure too high? Check pressure, add additional clamp.

Hose kinked or end blocked? Check hose.