ENGLISH

24

MAINTENANCE WORK ON CHASSIS AND ENGINE »

Maintenance and adjusting work marked with an asterisk * requires expert skills and technical know-how. For your own safety, always

have such work performed by a specialized KTM dealer where your motorcycle will be optimally serviced by appropriately qualified,

skilled staff.

– If using a power washer, do not point the water jet at the electric components, plugs, cables, bearings, carburetor, etc. The high

pressure will cause water to penetrate into the components and can cause them to malfunction or lead to premature wear.

– When transporting your KTM, ensure that it is held upright with restraining straps or other mechanical fastening devices and that

the fuel tap is in the OFF position - if the motorcycle should fall over, no fuel can leak from the carburetor or fuel tank

– Only use special screws with an appropriate thread length supplied by KTM to fix the spoilers on the tank. Using other screws or

longer screws can cause leaks in the tank through which fuel can flow out.

– Do not use toothed washers or spring rings with the engine fastening screws, as these work into the frame parts and keep working

loose. Instead, use self-locking nuts.

– If you unscrewed any screwed connections with self-locking nuts, they must be replaced when mounting. If no self-locking nuts

are available, apply Loctite 243 to the thread. The screws and nuts must be replaced if the thread is damaged.

– All screws and nuts must be tightened to the specified torque figures using a torque wrench. If screws or nuts are not adequately

tightened, they can become loose and cause the motorcycle to go out of control while you drive. Tightening the screws and nuts

too tightly can damage the thread and components.

– Let your motorcycle cool down before beginning any maintenance work in order to avoid getting burned.

– Dispose of oils, fatty matters, filters, fuels, washing detergents, etc. properly.

– Under no circumstances may used oil be disposed of in the sewage system or in the open countryside. 1 liter of used oil contam-

inates 1,000,000 liters of water.

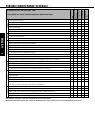

Changing the spring preloading of the shock absorber

The spring preload can be changed by turning the adjusting ring [1]. For this

purpose, you should dismount the shock absorber and clean it thoroughly.

NOTE:

– Before changing the spring preload note down the basic setting, e.g. how

many threads are visible above the adjusting ring.

– One rotation of the adjusting ring [1] changes the spring pretension by

approximately 1.75 mm (0.07 in).

Loosen the clamping screw [2] and use the hook wrench contained in the

vehicle tool set to turn the adjusting ring as desired. Turning it counterclock-

wise will reduce the preload, turning it clockwise will increase the preload.

After readjusting the clamping screw [2], tighten it to 8 Nm (6 ft.lb)

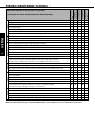

STANDARD SETTING – SPRING PRELOAD [A]

Typ WP Suspension 12187D02 . . . . .7 mm

Typ WP Suspension 12187D04 . . . . .7 mm

Typ WP Suspension 12187D27 . . . . .5 mm

Typ WP Suspension 12187D28 . . . . .5 mm

Typ WP Suspension 12187D33 . . . . .7 mm

Typ WP Suspension 12187D34 . . . . .8 mm

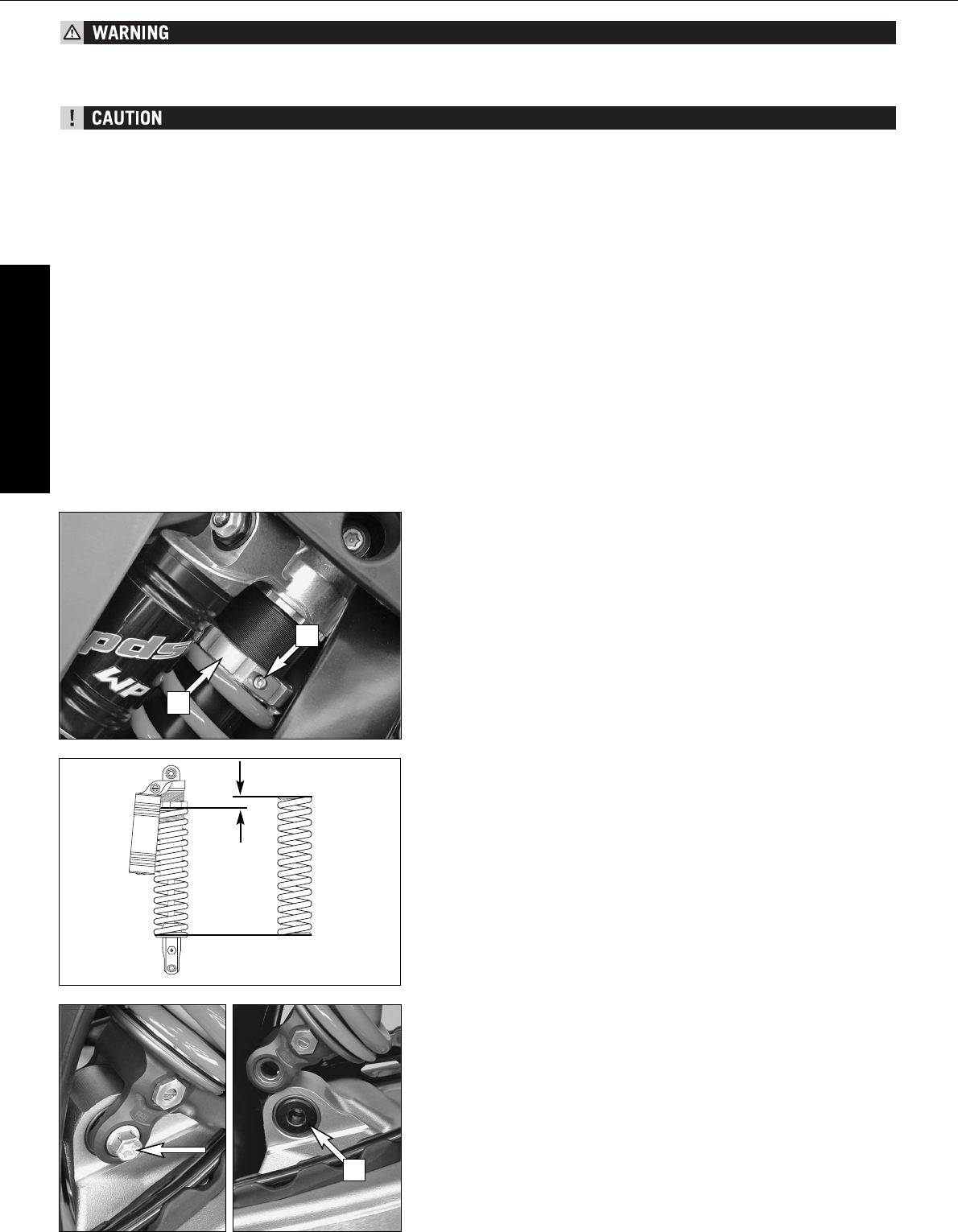

Pivot bearing

The pivot bearing [3] for PDS suspension struts at the swinging fork is Teflon-

coated and must not be lubricated with either grease or other lubricants. Grease

and other lubricants cause the Teflon coat to dissolve, whereby the bearing’s

lifecycle will be reduced dramatically.

When cleaning your bike with a high-pressure cleaner, do not aim the high-

pressure spray directly at the pivot bearing.

A

1

2

3