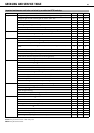

GREASING AND SERVICE TABLE 29

*5($6,1*$1'6(59,&(7$%/(

Important maintenance work to be carried out by an authorized KTM workshop.

S3N S15A S30A

Engine Change the engine oil and oil filter and clean the engine oil screen. ( P. 79) • • •

Change the gear oil and clean the gear oil screen. ( P. 82) • • •

Replace spark plug. •

Check and adjust valve clearance. • • •

Check engine mounting screws for tightness. • • •

Clean spark plug connectors and check for tightness. • • •

Check that the screws in the shift lever and the kickstarter are tight. • • •

Carburetor Check carburetor connection boots for cracks and leakage. • •

Check vent hoses for damage and routing without sharp bends. • • •

Check idle. •••

Attachments Check the cooling system for leakage. • • •

Check the antifreeze and coolant level. ( P. 71) • • •

Check the exhaust system for leakage and looseness. • •

Check Bowden cables for damage, smooth operation and routing without sharp

bends.

•••

Check the fluid level of the hydraulic clutch. ( P. 75) • • •

Clean the air filter. ( P. 75) • • •

Check cables for damage and routing without sharp bends. • •

Check that the electrical equipment is functioning properly. • • •

Check the headlamp setting. • •

Brakes Check the front brake linings. ( P. 57) • • •

Check the rear brake linings. ( P. 61) • • •

Check the brake discs. ( P. 55) • • •

Check the front brake fluid level. ( P. 56) • • •

Check the rear brake fluid level. ( P. 60) • • •

Check brake lines for damage and leakage. • • •

Check the free play of the hand brake lever. ( P. 55) • • •

Check the free play of the foot brake lever. ( P. 59) • • •

Check brake system function. • • •

Check screws and guide bolts of brake system for tightness. • • •

Chassis Check shock absorber and fork for leakage and functioning. • • •

Clean dust boots of fork legs. ( P. 39) • •

Bleed fork legs. ( P. 38) • •

Check swingarm bearing. ••

Check play of steering head bearing. ( P. 39) • • •

Check all screws to see if they are tight. • • •

Wheels Check the spoke tension. ( P. 67) • • •

Check rim run-out. • • •

Check the tire condition. ( P. 66) • • •

Checking the tire air pressure. ( P. 66) • • •

Check the chain wear. ( P. 52) • • •

Check the chain tension. ( P. 51) • • •

Clean the chain. ( P. 50) • • •

Check wheel bearing for play. • • •

Clean and grease adjusting screws of chain adjuster. • • •

S3N: After 3 service hours

S15A: Every 15 service hours / after every race

S30A: Every 30 service hours