ENGLISH

33

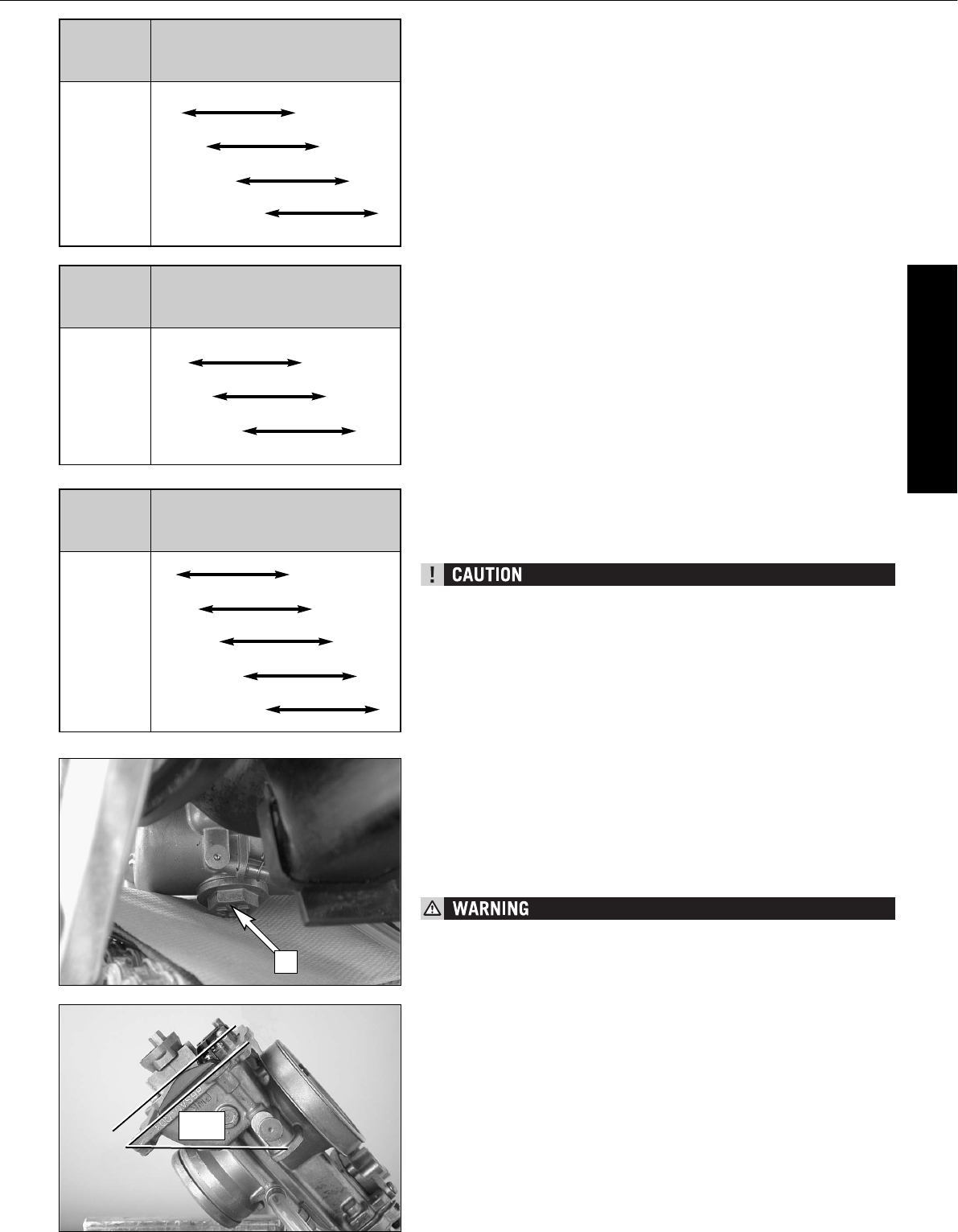

Draining the float chamber of the carburetor

Following every wet-cleaning procedure, the float chamber of the carburetor

should be drained in order to remove any water that may have penetrated into

it. Water in the float chamber leads to engine malfunction.

Make sure you do this while the engine is cold. Close the fuel tap, and place a

cloth under the carburetor, which is capable of absorbing the leaking fuel. Unscrew

the plug [1] and clean it with compressed air. Then, mount the plug together with

the gasket, open the fuel tap, and check the float chamber for leaks.

Fuel is easily flammable and toxic. When handling fuel, be sure to exercise

the utmost caution. Never perform any work on the fuel system near open

flames or burning cigarettes. Always allow the engine to cool off first.

Immediately clean up any fuel which may have been spilled. Materials satu-

rated with fuel are also easily flammable. In case you ingested fuel or fuel

splashed into your eyes, consult a doctor immediately.

Dispose of the fuel properly.

MAINTENANCE WORK ON CHASSIS AND ENGINE »

Explanation of table - Example

Compared to the needle N1EH, the jet needle N1EJ is two steps leaner in

the range from the closed position of the throttle to 1/4 throttle. Otherwise,

there are no differences.

Pay attention to the correct needle designation when replacing the jet nee-

dle. detailed information on the type of jet needle for the respective models

can be found in the carburetor setting table.

JET NEEDLE

TYPE

144 SX

RANGE OF ACTION

RICHER LEANER

R1470H

R1471H

R1472H

JET NEEDLE

TYPE

125 SX / SXS

RANGE OF ACTION

RICHER LEANER

R1468D

R1469D

R1470D

R1471D

JET NEEDLE

TYPE

250 SX / SXS

RANGE OF ACTION

RICHER LEANER

N1EF

N1EG

N1EH

N1EI

N1EJ

Checking the float level *

Arrange the carburetor diagonally at about 60° so that the spring in the float

needle valve is not pressed together. In this position, the edge of the float

should be parallel with the float chamber sealing surface (see illustration).

60°

1