11

NOTE: Operating the engine with a blocked grass

screen, dirty or plugged cooling fins, and/or

cooling shrouds removed, will cause engine

damage due to overheating.

Ignition System

These engines use an electronic Capacitive Discharge

(CD) ignition system. Other than periodically

checking/replacing the spark plugs, no maintenance,

timing, or adjustments are necessary or possible with

this system.

Check Spark Plugs

Every 100 hours of operation, remove the spark plugs,

check condition, and reset the gap or replace with new

plugs as necessary. The standard Courage spark plug

is a Champion

®

RC12YC (Kohler Part No.

12 132 02-S). RFI compliant engines use a Champion

®

XC12YC (Kohler Part No. 25 132 14-S) spark plug. A

high-performance spark plug, Champion

®

Platinum

3071 (Kohler Part No. 25 132 12-S) is standard on

Courage PRO models. Equivalent alternate brand

plugs can also be used.

1. Before removing the spark plug, clean the area

around the base of the plug to keep dirt and

debris out of the engine.

2. Remove the plug and check its condition. Replace

the plug if worn or reuse is questionable.

NOTE: Do not clean the spark plug in a machine

using abrasive grit. Some grit could remain in

the spark plug and enter the engine causing

extensive wear and damage.

3. Check the gap using a wire feeler gauge. Adjust

the gap to 0.76 mm (0.030 in.) by carefully

bending the ground electrode. See Figure 14.

4. Reinstall the spark plug into the cylinder head.

Torque the spark plug to 24.4-29.8 N·m

(18-22 . lb.).

Figure 14. Servicing Spark Plug.

Battery Charging

WARNING: Explosive Gas!

Baeries produce explosive hydrogen gas while being

charged. To prevent a fire or explosion, charge baeries only

in well ventilated areas. Keep sparks, open flames, and other

sources of ignition away from the baery at all times. Keep

baeries out of the reach of children. Remove all jewelry

when servicing baeries.

Before disconnecting the negative (-) ground cable, make

sure all switches are OFF. If ON, a spark will occur at the

ground cable terminal which could cause an explosion if

hydrogen gas or gasoline vapors are present.

Fuel System

Fuel Filter

Some engines are equipped with an in-line fuel filter.

Periodically inspect the filter and replace with a

genuine Kohler filter every 100 operating hours.

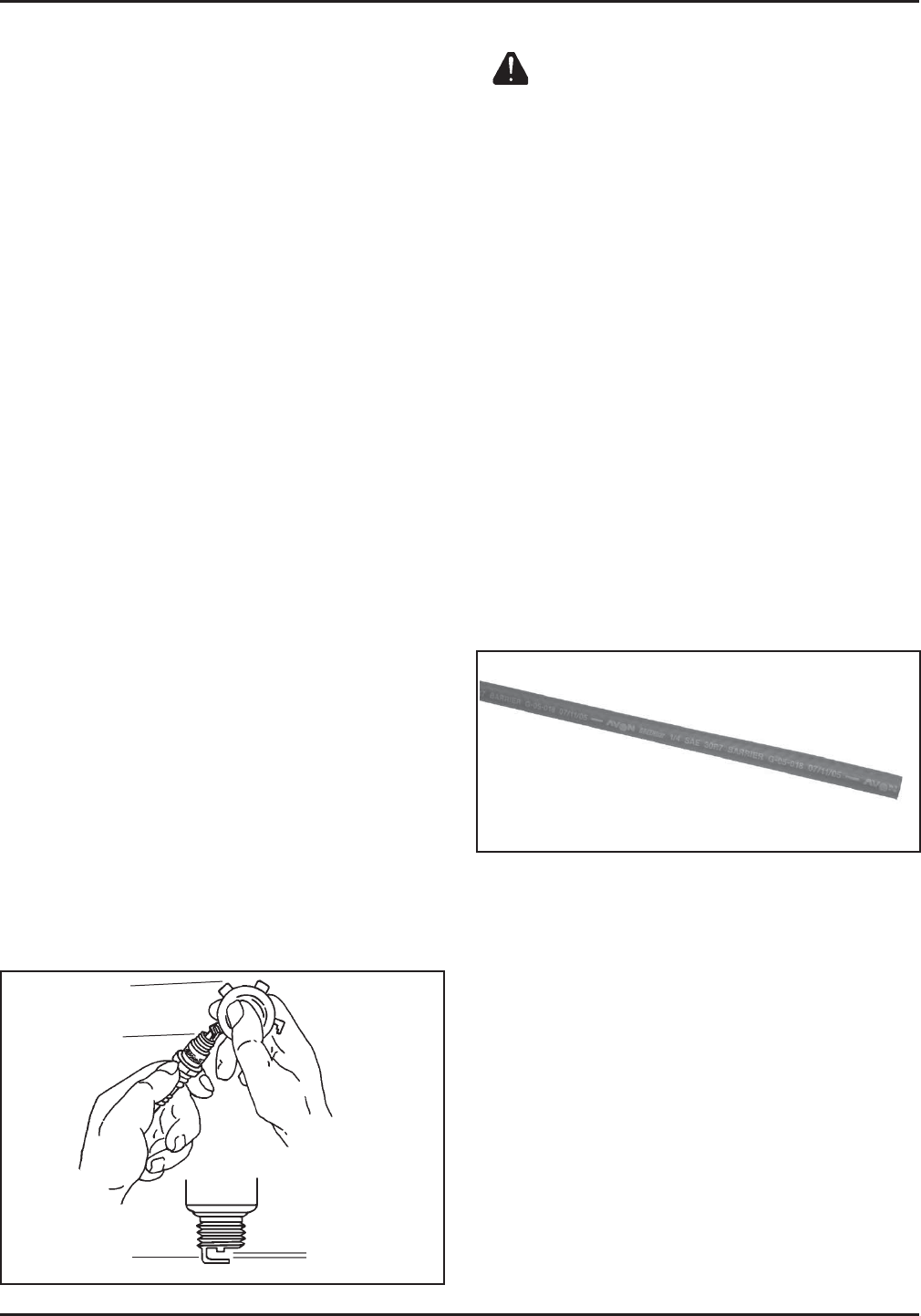

Fuel Line

In compliance with CARB Tier III Emission

Regulations, these engines use Low Permeation

SAE 30 R7 rated fuel line; certified to meet CARB

requirements. Standard fuel line may not be used.

Order replacement hose by part number through a

Kohler Engine Service Dealer.

Figure 15. Low Permeation Fuel Line.

Carburetor Troubleshooting and

Adjustments

In compliance with government emission standards,

the carburetor is calibrated to deliver the correct

fuel-to-air mixture to the engine under all operating

conditions. The high speed mixture is set at the factory

and cannot be adjusted. The low idle fuel adjustment

screw (if equipped) is also set at the factory and

normally does not require adjustment. See Figure 16.

Engines in this series depending on the model and

application, may also be equipped with a Governed

Idle System.

If the engine is equipped with a Governed Idle

System, refer to Models with Governed Idle System

when performing any carburetor adjustment, as an

additional step to the listed procedure(s) is required.

Wire Gauge

Ground

Electrode

Spark Plug

0.76 mm

(0.030 in.) Gap