7

EN

Congratulations on your purchase of a Kohler Engine. Every part, every component, every system on a

Kohler engine is guided by our exclusive Performance Engineering philosophy:

• To operate on the leading edge of innovation

• To push the boundaries of cleaner, more ecient engines

• To manufacture the highest performing, most reliable engines on the market

You can rest assured that your Kohler Engine will provide maximum power and reliability in all operating

conditions. Also, Kohler engines are backed by a worldwide network of over 10,000 distributors and dealers.

For more information on Kohler Engines or to nd a Kohler Service Center, visit KohlerEngines.com.

To keep your engine in top operating condition, follow the maintenance procedures in this manual.

Oil Recommendations

Using the proper type and weight of oil in the engine

is extremely important, as is daily checking of oil level

and changing oil regularly. Failure to use the correct

oil, or using dirty oil, will cause premature engine

wear and failure.

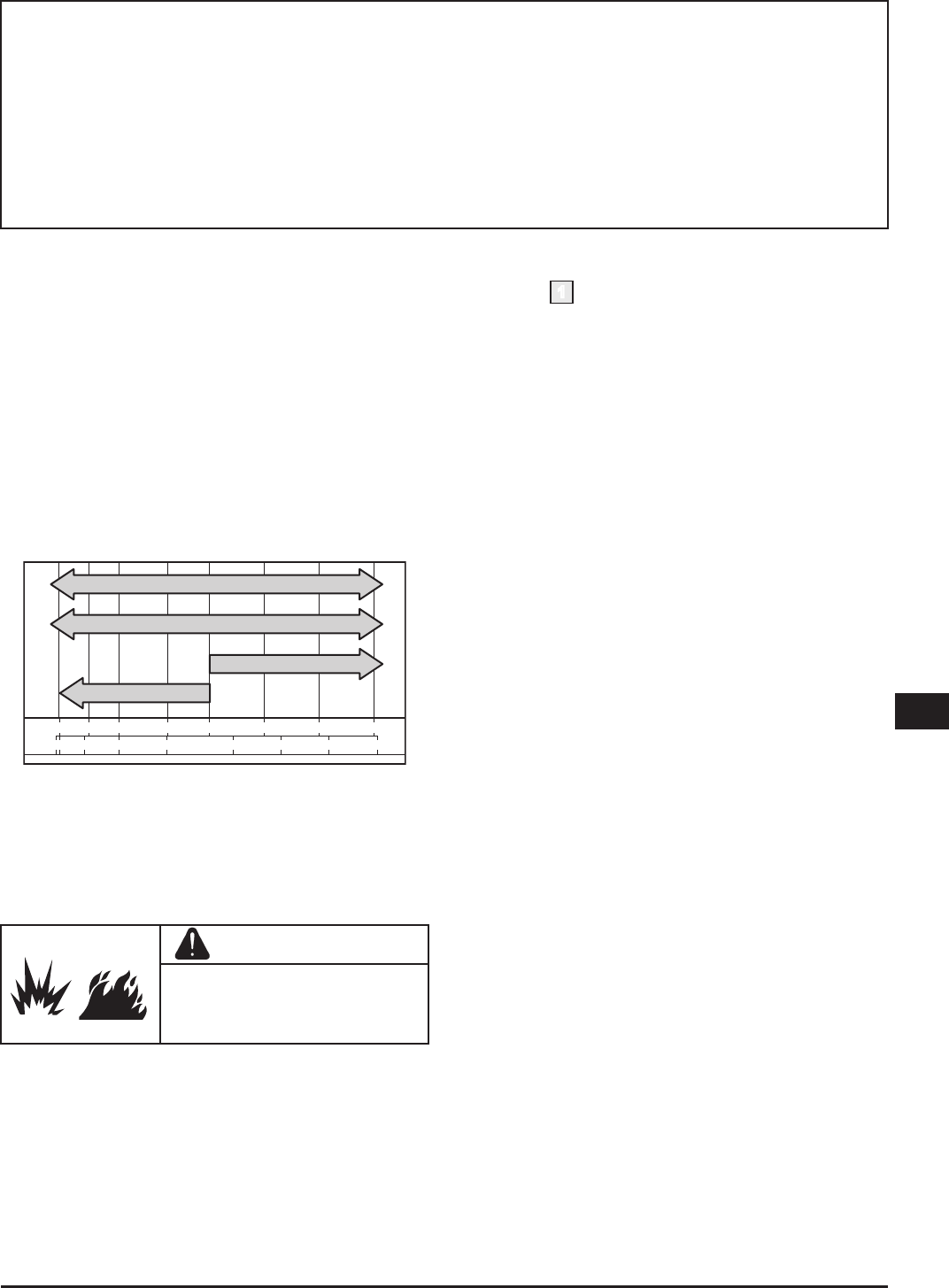

Oil Type

Use high-quality oil that ranks at or above the

American Petroleum Institute's (API) SJ service class.

Select the oil's viscosity based on air temperature at

the time of operation, as shown in the viscosity grades

table.

Recommended SAE Viscosity Grades

°F 0 20 32 40 60 80 100

°C -17

10

-12 -6 0 10 20 30 40

5W-30

10W-30

Kohler 10W-30

SAE 30

Use service class SJ rated oil or higher. Do not extend

the oil change intervals longer than recommended,

as this can cause engine damage and may void

the warranty. An API symbol on the oil container

identies the service class and SAE viscosity grade.

Fuel Recommendations

WARNING

Explosive Fuel can cause res

and severe burns.

Do not ll the fuel tank while the

engine is hot or running.

Gasoline is extremely ammable and its vapors can explode

if ignited. Store gasoline only in approved containers, in well

ventilated, unoccupied buildings, away from sparks or ames.

Do not ll the fuel tank while the engine is hot or running

since spilled fuel could ignite if it comes in contact with hot

parts or sparks from ignition. Do not start the engine near

spilled fuel. Never use gasoline as a cleaning agent.

General Fuel Recommendations

See Figure

1

Purchase gasoline in small quantities and store

in clean, approved containers. A container with a

capacity of 2 gallons or less with a pouring spout is

recommended. Such a container is easier to handle

and helps eliminate spillage during refueling.

To minimize gum deposits in your fuel system and to

ensure easy starting, do not use gasoline le over from

the previous season.

Do not add oil to the gasoline.

Do not overll the fuel tank (C). Leave room for the

fuel to expand.

Fuel Type

For best results use only clean, fresh, unleaded

gasoline with an octane rating of 87 or higher. In

countries using the Research method, it should be 90

octane minimum.

Unleaded gasoline is recommended as it leaves

less combustion chamber deposits and reduces

harmful exhaust emissions. Leaded gasoline is not

recommended.

Gasoline/Alcohol Blends

Gasohol (up to 10% ethyl alcohol, 90% unleaded

gasoline by volume) is approved as a fuel for Kohler

engines. Other gasoline/alcohol blends, including E20

and E85, should not be used. Failures resulting from

use of these fuels will not be warranted.

Gasoline/Ether Blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of 15% MTBE by

volume) are approved as a fuel for Kohler engines.

Other gasoline/ether blends are not approved.

Fuel Line

These engines use Low Permeation SAE 30 R7 rated

fuel lines, certied to meet emission requirements.

Standard fuel lines may not be used. Order

replacement hose through a Kohler Service Center.

Operating Instructions

Also read the operating instructions of equipment this

engine powers.