16

• Make sure the air cleaner element and precleaner

are clean and properly secured.

• Make sure the air intake screen, blower housing,

and cooling surfaces of radiator are clean and free

of dirt and debris.

If, after checking the items listed above, the engine is

hard to start, runs roughly, or stalls at low idle speed, it

may be necessary to adjust or service the carburetor.

Adjust Carburetor

Start the engine and run at half throttle for 5 to 10

minutes to warm up. The engine must be warm before

making final settings.

Low idle speed (RPM) setting:

1. Place the throttle control into the idle or slow

position. Set the low idle speed to 1200 RPM*

(± 75 RPM) by turning the low idle speed adjusting

screw (cable w/knob on some models) in or out.

Check the speed using a tachometer.

*NOTE: The actual low idle speed depends on the

application – refer to equipment

manufacturers recommendations. The

standard low idle speed is 1200 RPM.

2. If proper operation is not restored after adjusting

the low idle speed, carburetor servicing by an

authorized Kohler Engine Service Dealer may be

required.

Electronic Fuel Injection (EFI) System

The EFI system is a complete, electronically-controlled

fuel management system, designed to deliver a

precisely controlled fuel flow under all operating

conditions. The electronic control unit (ECU), the

‘‘brain’’ of the system, automatically adjusts fuel

delivery and ignition timing based upon load, speed,

operating temperature, and exhaust emission levels.

The low idle speed is the only manual adjustment

possible.

The ECU continuously monitors operation of the EFI

system. If it detects a problem or fault within the

system, it will illuminate the malfunction indicator

light (MIL), which is mounted in view of the operator.

This is a signal that normal, programmed operation

has been affected, and service by an authorized Kohler

Engine Dealer is required.

NOTE: The EFI system requires a rather complex

wiring harness to carry the electrical signals

between the sensors and the ECU. Do not

spray water at the wiring harness or any of

the electrical components, especially the ECU,

as it could cause malfunction, damage, or

failure.

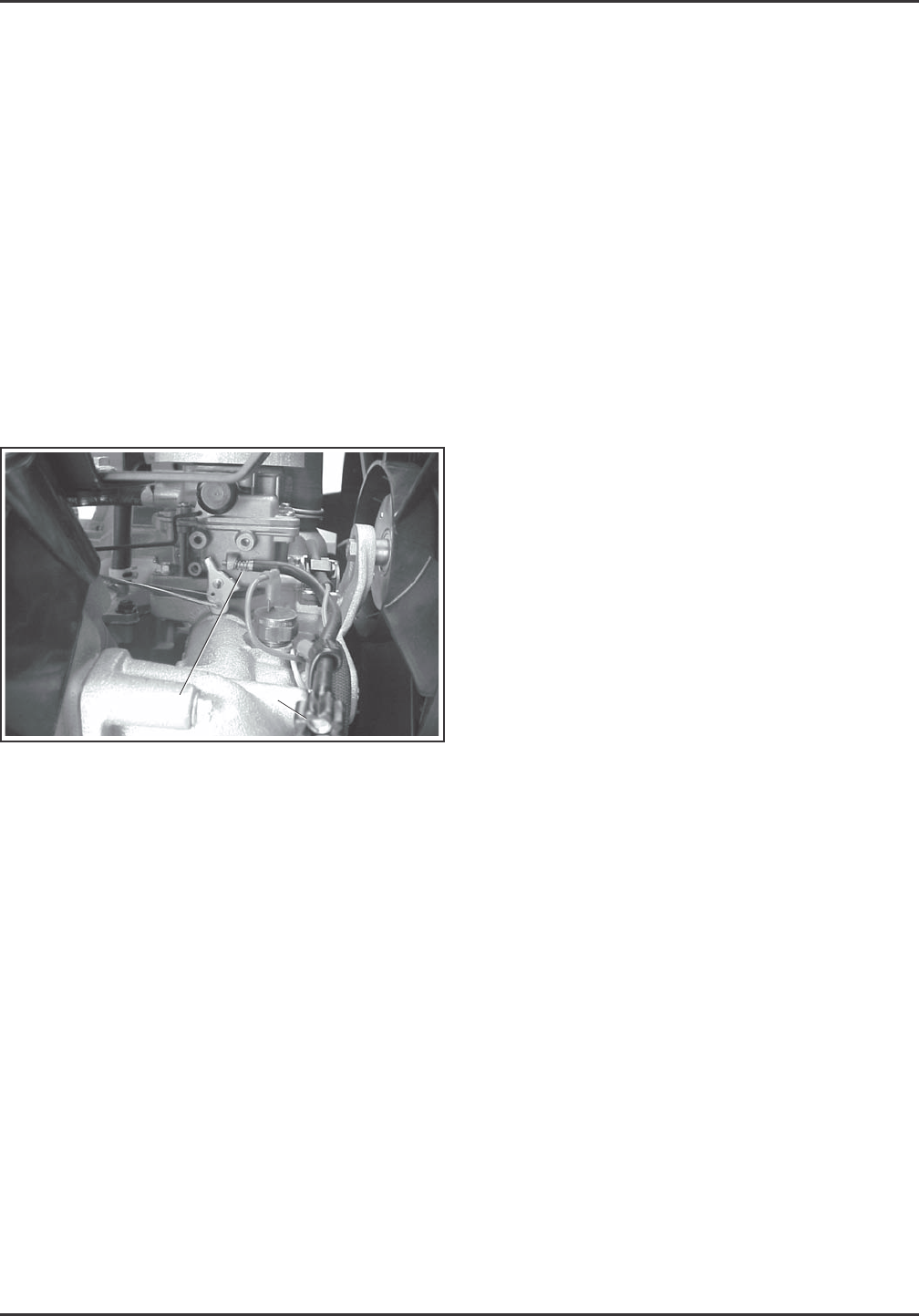

Carburetor Troubleshooting and

Adjustments

In compliance with the government emission

standards, the carburetor is calibrated to deliver the

correct fuel-to-air mixture to the engine under all

operating conditions. The carburetor cannot be

adjusted, except for low idle speed (RPM). Carburetor

servicing is to be performed by an authorized Kohler

Engine Service Dealer only. See Figure 26.

NOTE: To ensure correct engine operating at

altitudes above 1525 meters (5000ft.), it may

be necessary to have an authorized Kohler

dealer install a special high-altitude jet kit in

the carburetor. If a high-altitude kit has been

installed, the engine must be reconverted to

the original jet size, before it is operated at

lower altitudes, or overheating and engine

damage can result.

Idle Speed Adj.

Knob

Figure 26. Carburetor and Idle Speed Adjustment.

Troubleshooting

If engine troubles are experienced that appear to be

fuel system related, check the following areas before

adjusting the carburetor.

• Make sure the fuel tank is filled with clean, fresh

gasoline.

• Make sure the fuel tank cap vent is not blocked

and that it is operating properly.

• If the fuel tank is equipped with a shut-off valve,

make sure it is open.

• If the engine is equipped with an in-line fuel filter,

make sure it is clean. Replace the filter if it is dirty

or restricted.

• Make sure fuel is reaching the carburetor. This

includes checking the fuel lines and fuel pump for

restrictions or faulty components, replace as

necessary.

• Make sure cooling system is filled to the proper level.