5

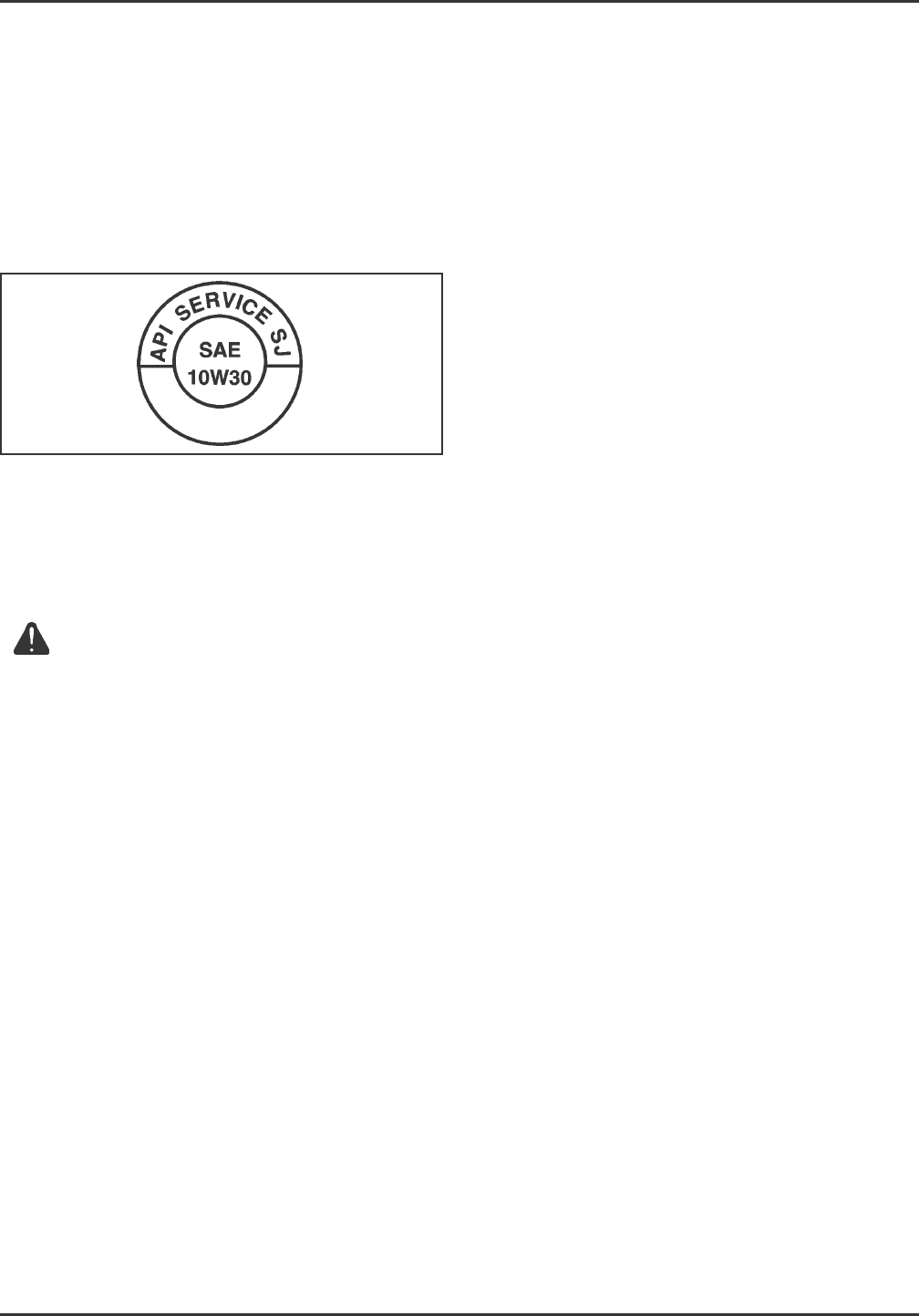

Figure 4. Oil Container Logo.

Refer to Maintenance Instructions beginning on

page 8 for detailed oil check, oil change, and oil filter

change procedures.

Fuel Recommendations

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can explode if

ignited. Store gherasoline only in approved containers, in well

ventilated, unoccupied buildings, away from sparks or flames.

Do not fill the fuel tank while the engine is hot or running,

since spilled fuel could ignite if it comes in contact with hot

parts or sparks from ignition. Do not start the engine near

spilled fuel. Never use gasoline as a cleaning agent.

General Recommendations

Purchase gasoline in small quantities and store in

clean, approved containers. A container with a

capacity of 2 gallons or less with a pouring spout is

recommended. Such a container is easier to handle

and helps eliminate spillage during refueling.

Do not use gasoline left over from the previous season,

to minimize gum deposits in your fuel system and to

insure easy starting.

Do not add oil to the gasoline. Do not overfill the fuel

tank. Leave room for the fuel to expand.

Fuel Type

For best results use only clean, fresh, unleaded

gasoline with the pump sticker octane rating of 87 or

higher. In countries using the Research method, it

should be 90 octane minimum.

Unleaded gasoline is recommended as it leaves less

combustion chamber deposits and reduces harmful

exhaust emissions. Leaded gasoline is not

recommended and must not be used on EFI engines, or

on other models where exhaust emissions are

regulated.

Gasoline/Alcohol blends

Gasohol (up to 10% ethyl alcohol, 90% unleaded

gasoline by volume) is approved as a fuel for Kohler

engines. Other gasoline/alcohol blends including E20

and E85 are not to be used and not approved. Any

failures resulting from use of these fuels will not be

warranted.

Gasoline/Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of 15% MTBE by

volume) are approved as a fuel for Kohler engines.

Other gasoline/ether blends are not approved.

Coolant Recommendations

Use equal parts of ethylene glycol (anti-freeze) and

water only. Distilled or deionized water is

recommended, especially in areas where the water

contains a high mineral content. Propylene glycol

based anti-freeze is not recommended.

This mixture will provide protection from -37°C

(-34°F) to 108°C (226°F). For protection and use outside

the indicated temperature limits, follow the anti-

freeze manufacturers instructions on the container,

but do not exceed 70% anti-freeze.

DO NOT use anti-freeze with stop-leak additive(s), or

put any other additives in the cooling system.

Engine Identification Numbers

When ordering parts, or in any communication

involving an engine, always give the Model,

Specification, and Serial Numbers of the engine.

The engine identification numbers appear on a decal,

affixed to the engine. The primary location is on the

side of the flywheel cover. Placement may vary due to

OEM requirements and specific options involved.

Record your engine identification numbers on the

identification label (Figure 5) for future reference.

NOTE: Synthetic oils meeting the listed

classifications may be used with oil changes

performed at the recommended intervals.

However to allow piston rings to properly

seat, a new or rebuilt engine should be

operated for at least 50 hours using standard

petroleum based oil before switching to

synthetic oil.

A logo or symbol on oil containers identifies the API

service class and SAE viscosity grade. See Figure 4.