MAINTENANCE

TP-6901 6/14 Maintenance 25

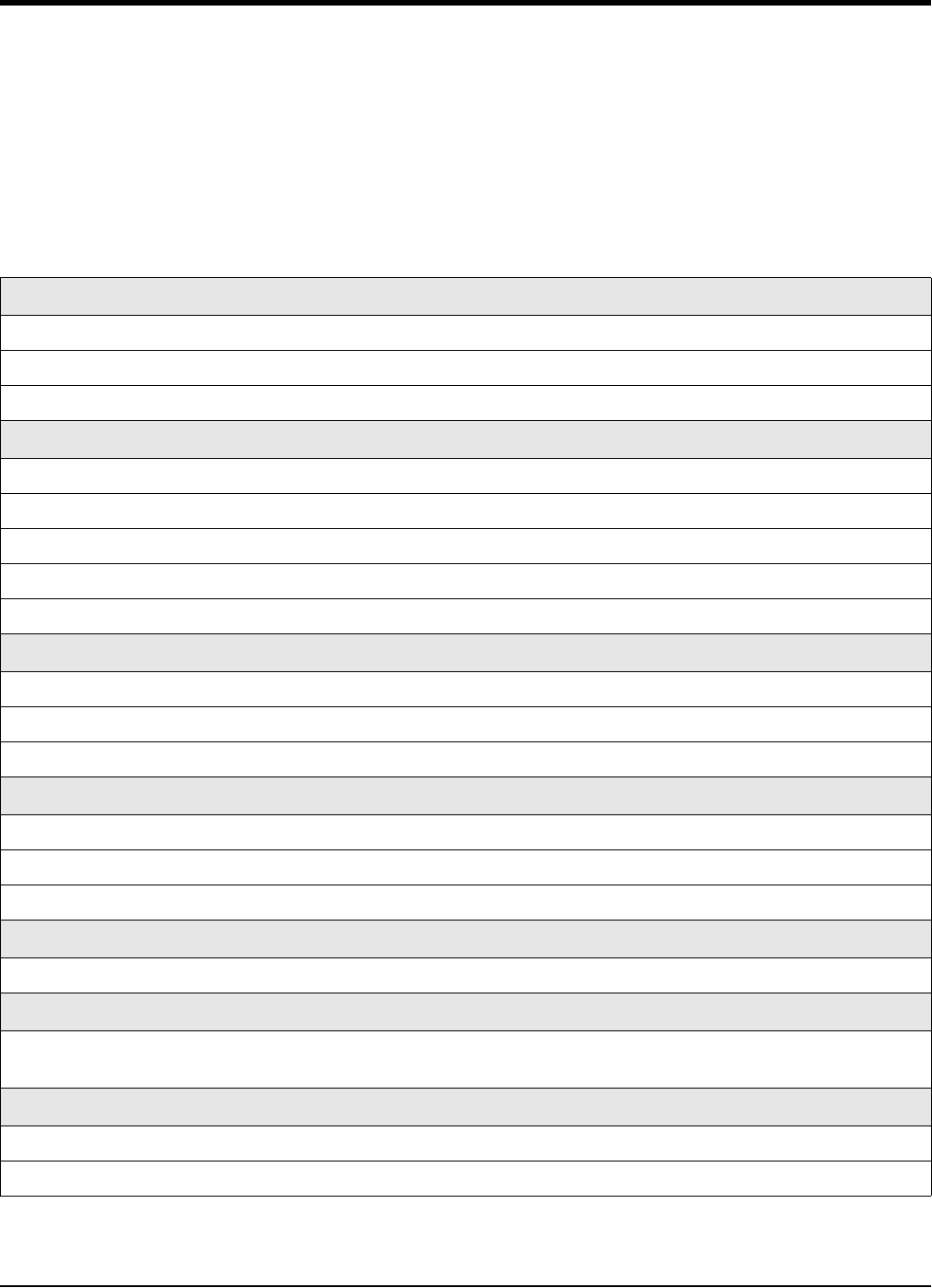

5.3 PERIODIC MAINTENANCE SCHEDULE

Engine parts experience wear at different rates. Technical maintenance tasks, therefore, are required at several

different intervals throughout the life of the engine:

• Daily

• Weekly or every 10 hours of operation

• Quarterly or every 20 hours of operation

• Yearly or every 120 hours of operation

• 3 Years or every 400/500 hours of operation

• Seasonally

The chart lists the required maintenance tasks at each designated intervals throughout the life of the engine.

For example, a task performed after the first 10 hours of operation must be repeated after 20 hours, 30 hours,

and so forth.

Daily (before starting)

• Check for loose or missing fasteners. Tighten or replace as needed.

• Check the level of fuel, coolant, and oil. Refill as needed.

• Check coolant system hoses and clamps.

Weekly or every 10 hours of operation

• Check battery connections for tightness and signs of corrosion.

• Check for oil and coolant leaks.

• Check wiring and electrical connections. Repair or replace loose or damaged components.

• Start engine and listen for abnormal noises.

• Check for fuel system leaks, hissing sounds, or gas odor.

Quarterly or every 20 hours of operation

• Check battery voltage; charge or replace as needed.

• Check and clean air filter. (See equipment Operation Manual.)

• Check all fasteners for tightness.

Yearly or every 120 hours of operation

• Check the battery for cracks, damaged electrodes, and corrosion.

• Check the drive-belt tension. Adjust or replace drive belt if necessary.

• Replace engine oil and oil filter.

3 years or every 400 hours of operation

• Change air filter element(s). (See equipment Operation Manual.)

3 years or every 500 hours of operation

• Check spark plug condition and electrode gap. Adjust gap if necessary. Replace spark plug(s) if discolored or

damaged.

Seasonal Maintenance

• Check coolant concentration and replenish/replace as needed.

• Replace engine oil with a lower temperature grade in the winter (if required).