13

4. Reinstall the spark plug into the cylinder head.

Torque the spark plug to 24.4-29.8 N·m

(18-22 ft. lb.).

Battery Charging

WARNING: Explosive Gas!

Batteries produce explosive hydrogen gas while being charged.

To prevent a fire or explosion, charge batteries only in well

ventilated areas. Keep sparks, open flames, and other sources of

ignition away from the battery at all times. Keep batteries out of

the reach of children. Remove all jewelry when servicing

batteries.

Before disconnecting the negative (-) ground cable, make sure

all switches are OFF. If ON, a spark will occur at the ground

cable terminal which could cause an explosion if hydrogen gas

or gasoline vapors are present.

NOTE: Do not apply 12 volt DC to kill terminal of

ignition module.

Fuel System

Fuel Filter

Most engines are equipped with an in-line fuel filter.

Periodically inspect the filter and replace with a

genuine Kohler filter seasonally or every 150

operating hours.

Fuel Line

These engines use Low Permeation SAE 30 R7 rated

fuel line; certified to meet emission requirements.

Standard fuel line may not be used. Order

replacement hose by part number through a Kohler

Engine Service Dealer.

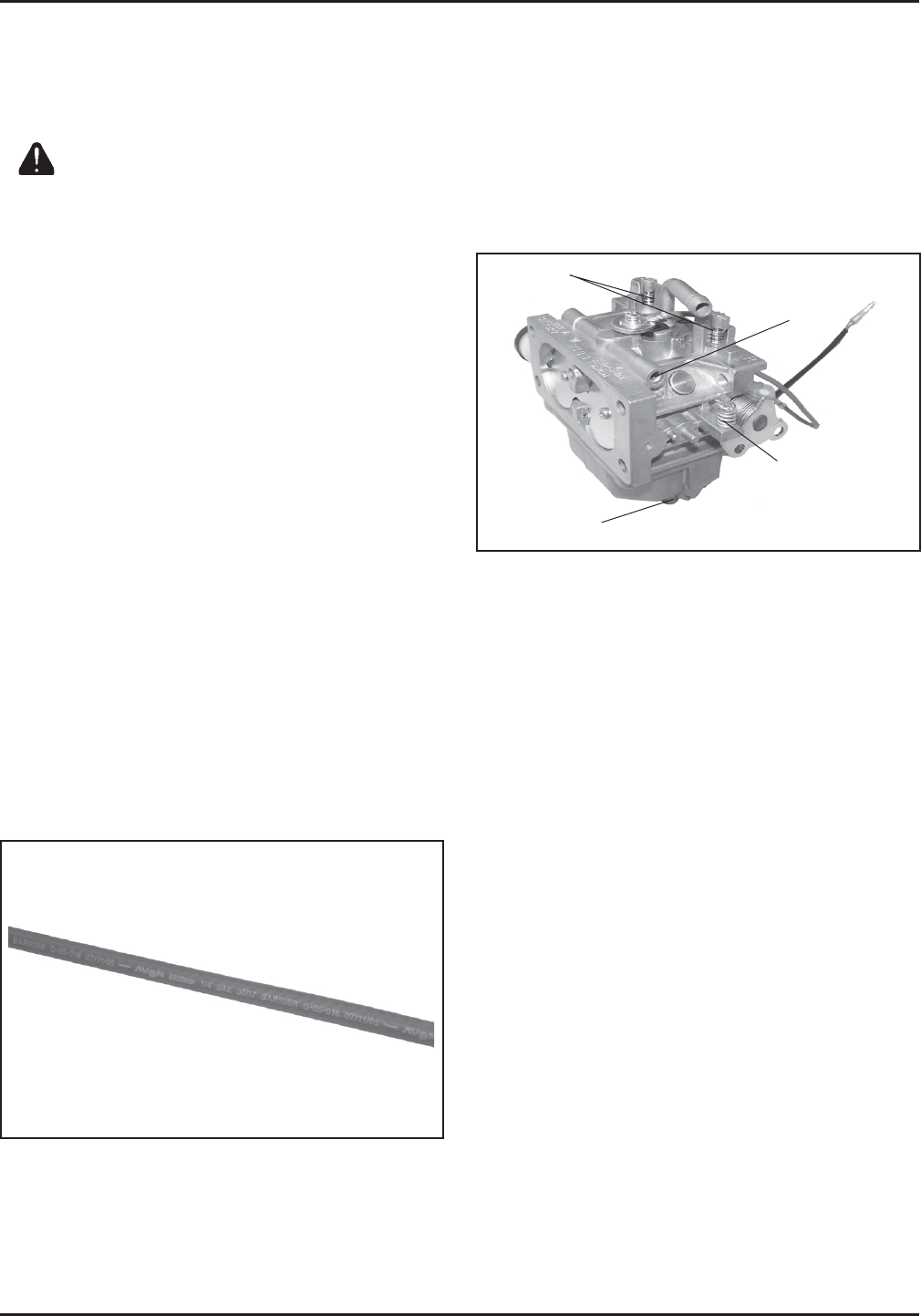

Figure 25. Keihin Two-Barrel Carburetor.

NOTE: Carburetor adjustments should be made

only after the engine has warmed up.

NOTE: To ensure correct engine operation at

altitudes above 1525 meters (5000 ft.), it may

be necessary to have an authorized Kohler

dealer install a special high-altitude jet kit in

the carburetor. If a high-altitude kit has been

installed, the engine must be reconverted to

the original jet size, before it is operated at

lower altitudes, or overheating and engine

damage can result.

Troubleshooting

If engine troubles are experienced that appear to be

fuel system related, check the following areas before

adjusting the carburetor.

• Make sure the fuel tank is filled with clean, fresh

gasoline.

• Make sure the fuel tank cap vent is not blocked

and that it is operating properly.

• If the fuel tank is equipped with a shut-off valve,

make sure it is open.

• If the engine is equipped with an in-line fuel filter,

make sure it is clean and unobstructed. Replace

the filter if necessary.

Figure 24. Low Permeation Fuel Line.

Carburetor Troubleshooting and

Adjustments

These engines use a Keihin BK two-barrel carburetor

with fixed main jets, and fixed or limiter-equipped

low idle fuel adjusting needles. See Figure 25. In

compliance with government emission standards, the

carburetor is calibrated to deliver the correct fuel-to-

air mixture to the engine under all operating

conditions. Adjustments are made as follows.

Drain Screw

Idle Speed (RPM)

Adjustment Screw

Idle Fuel

Adjustments

Vacuum Port