6

6.0 Assembly

Numbers in parenthesis (#) refer to parts

breakdown, page 6:

1. Insert Upper Handle (30) into Lower Handle

(29) and fasten with Hex Cap Bolt (28).

2. Remove Handle Bolt (25).

3. Insert handle assembly into Handle Socket

(23). Make sure handle assembly engages

Gear Shaft (27) by turning handle back and

forth and observing movement of Handle

Socket Gear (26).

4. Install Handle Bolt (25) to secure handle

assembly.

7.0 Lubrication

Note: Lubricate before initial operation, and

periodically to ensure smooth operation.

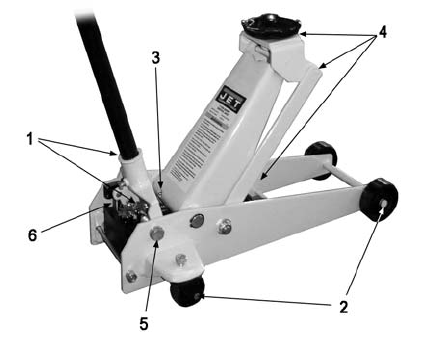

Lubricate jack at points 1 through 6, as indicated

in Figure 1.

Figure 1 – Lubrication points

1. Handle: Use #2 tube grease on release

valve gears below handle and lightly grease

handle at point where it fits into socket.

2. Wheels: Use 30W oil on axles and caster

bearings.

3. Lifting Arm: Inject #2 tube grease into

grease fitting.

4. Saddle and linkage: Use 30W oil on all

moving and pivoting parts.

5. Handle socket pivot bolts: Lubricate with

30W oil.

6. Plunger and plunger pin: Use #2 tube

grease to lubricate connection between

pump plunger and pin in handle socket.

8.0 Operating instructions

Important: During shipment and handling, air

sometimes gets into the hydraulic system

causing poor lifting performance. Before initial

operation, purge any air from system by fully

opening pump release valve (turn handle

counter-clockwise). Then, while holding saddle

down, pump handle rapidly several times.

8.1 Raising the jack

1. Close release valve by turning handle

clockwise until resistance is felt. Do not over

tighten.

2. Place jack directly under object to be lifted,

and pump handle to raise saddle to contact

point. Make sure saddle accepts weight

firmly and centrally.

3. Check positioning under slight load to

confirm jack or load will not slip, or move

suddenly.

4. Raise jack by pumping handle until desired

height is reached.

5. After lifting, secure and transfer load to jack

stands or other appropriate means. Do not

use jack as the only means of support.

8.2 Lowering the jack

Slowly turn handle counter-clockwise. Speed of

descent is controlled by amount release valve is

turned.

9.0 Maintenance

Store jack in a safe and dry environment, away

from children or unauthorized personnel. Always

store jack in fully lowered position, with handle in

upright position.

Keep jack clean and properly lubricated.