HEMMINGS SPORTS & EXOTIC CAR

•

october 2007 hemmings.com

26

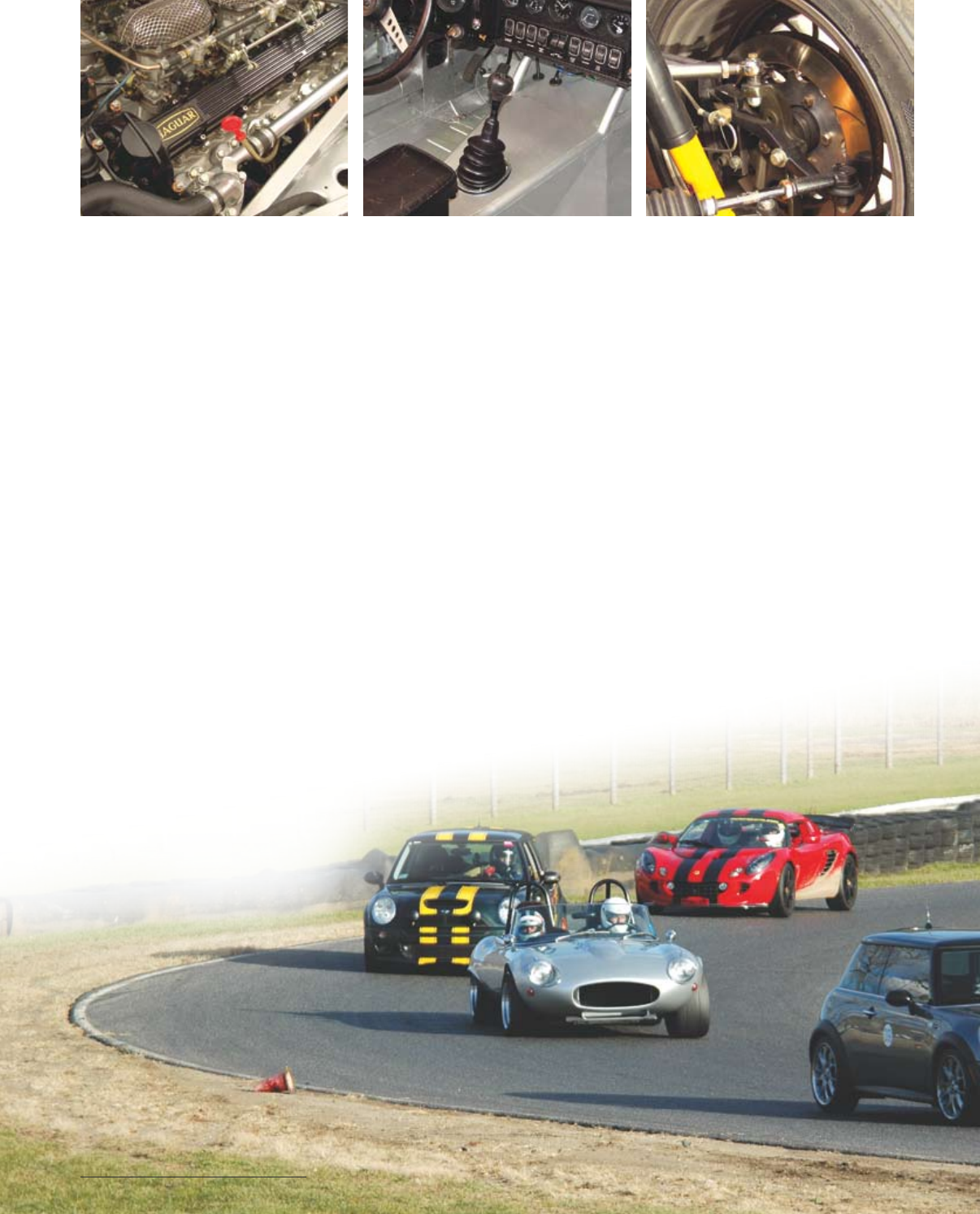

ENGINE

As fitted to a Series III E-Type, the stock 5.3-

liter V-12 is only 86 pounds heavier than its

4.2-liter straight-six predecessor, and uses

four Zenith-Stromberg 175 CD 2SE carbure

-

tors. The engine in The Beast is a highly modi

-

fied 7.3-liter unit that uses an 84mm Jaguar

Racing forged crankshaft, 96mm Cosworth

pistons, Carrillo connecting rods and 1.8-

inch inlet/1.4-inch exhaust valves with .501

lift. With an 11.6:1 compression ratio and six

44mm Weber IDF carburetors, it makes 600hp

and 578-lbs.ft. of torque.

“The Beast is over the top, but there are a

lot of cost-effective ways to modify the Series

III V-12 for more power,” Stew says. “With

the short stroke, the 5.3-liter is a durable

engine that goes and goes. But instead of

trying to get more power from a 5.3, it’s

easy to increase the cubic inches without

giving away low-speed driveability. You can

combine the longer crank of the late 6.0-liter

engine with 6mm overbore pistons and liners

and a mild, streetable cam, and you’ll have

a 6.8-liter making between 350 and 375hp,

which is pretty exciting in a 3,200-pound car.

The Stromberg carburetors can be made to

work very well, and two-inch SUs are a mid-

level upgrade before Webers.

“E-Types are notorious for overheating,

and I insist on cooling upgrades on every car

I work on, including a Ron Davis aluminum

radiator, electric cooling fans, a 165-degree

thermostat and an Airpax commercial-level

fan switch, which fits in a special housing

that I developed. The weak stock ignition sys

-

tem is cured with SNG Barratt’s Opus Ignition

Replacement HE upgrade.”

DRIVELINE

Stew notes that many Series III E-Types were

fitted at the factory with three-speed Borg

Warner M12 automatic gearboxes—he esti

-

mates that half of FHC models and roughly

a third of OTS models were so equipped. It

is possible to retrofit an automatic V-12 car,

as well as an original four-speed manual car,

with a modern overdrive five-speed trans-

mission. “The most difficult part is finding

a good pedal assembly. Once you get the

assembly, everything else is available new,”

he explains. “Tremec T5s engineered for E-

Types by Medatronics are readily available,

and T5s are common and relatively inexpen

-

sive. The cost for rebuilding a Jaguar four-

speed is halfway to a T5 conversion!”

The Beast uses a Euro-spec XJ-S-sourced

Getrag five-speed, a three-disc Tilton

Engineering carbon/carbon clutch and a

3.78:1 ratio Detroit Locker rear differential.

“The Beast is a slalom/autocross/track car

that is subjected to severe 80-foot turns, and

because of its Detroit Locker, it could chew

up output shafts. We use Mark Williams

hardened axles, but if you’re not building

a slalom car, this won’t be an issue, and

Jaguar’s positraction rear is quite sufficient.

I like running 3.54 rear gears with a five-

speed.”

BRAKES

Jaguars were using four-wheel disc brakes,

with ventilated 11-inch front rotors, for years

before their competition, and Stew feels

that, if properly cooled, the stock Series III

units are very capable. “The Beast uses 13-

inch front discs with six-piston calipers, and

the rear brakes are ventilated Porsche discs

with four-piston calipers. The only reason

I picked the Porsche discs was because of

their size and ventilation; Bob Green’s BG

Developments in England sells cost-effective

ventilated rear discs and spacers in the stock

diameter, ” he says. “There’s very little room

to expand brake size with the inboard sus-

pension cage.”

Stew enhanced The Beast’s braking ventila

-

tion by rerouting the original passenger com-

partment air ducts to feed air to the front

brakes. “Jaguar designed bolt-on ducts that

stuck out below the car, ahead of the rear

wheels,” he says. “On most E-Types, these

are long gone, either smashed flat or possibly

never installed by the dealer. I added exit ple

-

nums that pull air from above the rear discs

and send it through hoses that exit where

the license plate lamp used to be.”