OPERATING INSTRUCTIONS

PAGE 3 OF 8

651615-X

LIFT/RAM INSTALLATION

WARNING Failure to properly install the lift assembly can

result in severe personal injury and property damage. Read

the warning on page 2.

1. Establish the desired location for the lift/ram and pay special attenĆ

tion to work area above, this area above the lift must be open, withĆ

out obstructions and safely away from any electrical devices.

2. Place the pump on the follower plate and align the pump and folĆ

lower plate onthe baseand assemblepump tothe mountingbrackĆ

et on the ram.

3. Assemble air hose to air motor inlet.

4. Install the check and follower plate air hose from the Control Valve.

5. Assemble the vent plug to the follower plate.

NOTE: The ram was tested at the factory. The unit should be generally

checked over for leakage because the fittings on the system may have

loosened in shipment.

OPERATING INSTRUCTIONS / INITIAL SETUP PROCEDURE

WARNING STAND CLEAR. When raising or lowering the

lift. Read the warning on page 2.

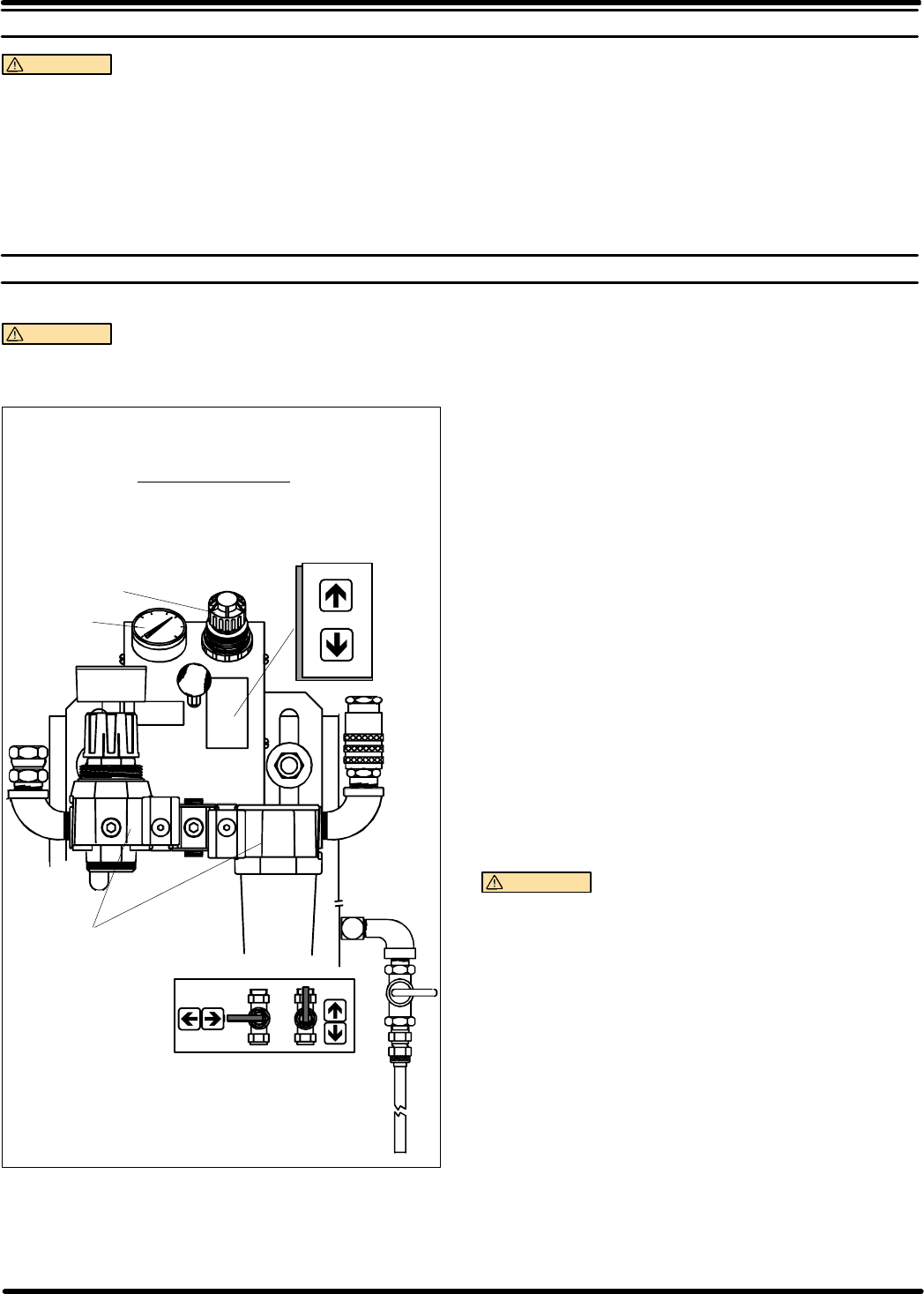

PRESSURE

REGULATOR

FOLLOWER PLATE

AIR SUPPLY VALVE

CONTROL

LEVER

GAUGE

AIR CONTROLS

FIGURE 2

OFF

ON

UP

NEUTRAL

DOWN

PUMP

FILTER-REGULATOR

TO RAISE LIFT, (THE FIRST TIME):

1. Take note of the pump/drum clearance above. Be certain the lift is

clear of any objects above. Also refer to OPERATING AND SAFEĆ

TY PRECAUTIONS found on page 2.

2. Connect the air supply (160 PSI MAX) to the air inlet.

3. Shift the control valve lever to the ``UP'' position.

4. Raise the lift high enough to clear the height of the drum. Stop the

lift upward travel by moving the control valve lever to the (center)

``NEUTRAL'' position.

TO RAISE LIFT, (NORMAL OPERATION):

1. Adjust the Follower Plate Air Valve pressure up to approximately 8

psig. DO NO OVERPRESSURIZE THE DRUM to avoid damage.

NOTE: Air from this valve will only pass when the Control Lever is

in the ``UP'' position.

2. Shift the control valve lever to the ``UP'' position.

3. Raise the lift high enough to clear the height of the drum. Stop the

lift upward travel by moving the control valve lever to the (center)

``NEUTRAL'' position.

TO CHANGE DRUM:

NOTE: The Control Lever should be in the ``NEUTRAL'' position.

1. Place a new drum into position.

TO LOWER LIFT:

WARNING

PINCH HAZARD. Follower can descend quickly

causing injury. Keep hands clear when aligning with containĆ

er. Read the warning on page 2.

NOTE: Be certain the Follower Plate vent plug has been removed so

that the air trapped between the follower and the material is allowed to

escape from this vent. Captured air between the follower plate and

drum will escape.

NOTE: The lift may hesitate momentarily before starting downward,

the air pressure insidethe post air chamber mustdecrease before it will

begin to descend.

1. Shift the control valve leverto the``DOWN''position andproceed to

lower the pump.

2. Replace the vent plug once the material begins to ooze from the

vent opening.