650891-X-B

PUMP OPTION DESCRIPTION CHART

650891- X

PACKING MATERIAL

PLUNGER TYPE

SPRING ARRANGEMENT

PACKING MATERIAL (PACKINGSARE UPPERANDLOWERUNLESS NOTED)

3 Glass Filled PTFE P UHMW- PE / PTFE Stag’d (Upper)

C UHMW-PE UHMW-PE (Lower)

G UHMW-PE / Leather Staggered R PTFE / UHMW-PE Stag’d (Upper)

Glass Filled PTFE (Lower)

SPRING ARRANGEMENT

PLUNGER TYPE

4 Multiple Wave Spring 7 HD SS W / HD Chrome Plating

47-B

GENERAL DESCRIPTION

WARNING

HAZARDOUS PRESSURE. Do not exceed maxi-

mum operating pressure of 5964 p.s.i. (411.3 bar) at 120 p.s.i.

(8.3 bar) inlet air pressure.

PUMP RATIO X

INLET PRESSURE TO PUMP MOTOR

=

MAXIMUM PUMP

FLUID PRESSURE

Pump ratio is anexpression of therelationship betweenthe pump motorarea andthe

lowerpumpendarea.EXAMPLE:When120p.s.i.(8.3bar)inletpressureissuppliedto

themotorofa4:1ratiopumpitwilldevelopamaximumof480p.s.i.(33.1bar)fluidpres-

sure(atno flow) --asthe fluidcontrolis opened,theflowratewillincreaseasthemotor

cycle rate increases to keep up with the demand.

WARNING

Refer to general information sheet for additional

safety precautions and important information.

• The Chop -Check pumps areprimarily designed for the pumpingof

heavy viscous material with or without fibrous content. The models

can be used with a gravity feed single post lift as a topper type as-

semblyor witha twopostlift asa forcefeed typeassembly.The low-

er pump is designed for easy priming and the double acting feature

is standard i n all ARO industrial pumps. Material is delivered to the

pump discharge outlet on both the up and down stroke.

• The motor is connected to the lower pump end by a spacersection.

This allows for lubrication of the upper packing gland and prevents

motorcontamination becauseof normalwearand eventualleakage

through the material packing gland. Be sure the solvent cup is ade-

quately filledwith lubricantto protect the upperpackings and insure

longest service life.

TROUBLE SHOOTING

Pump problems can occur in either the Air Motor Section or the Lower

Pump EndSection. Use these basicguidelines to help determinewhich

section is affected.

If the pump will not cycle.

• Becertaintofirst checkfornon-pumpproblemsincludingkinked,re-

strictive or plugged inlet /outlet hose or dispensing device. Depres-

surize the pump system and clean out any obstructions in the inlet /

outlet material lines.

• Refer to the motor manual for trouble shootingif the pump does not

cycle and / or air leaks from the air motor.

If the pump cycles but does not deliver material.

• Refer to the lower pump end manual for further trouble shooting.

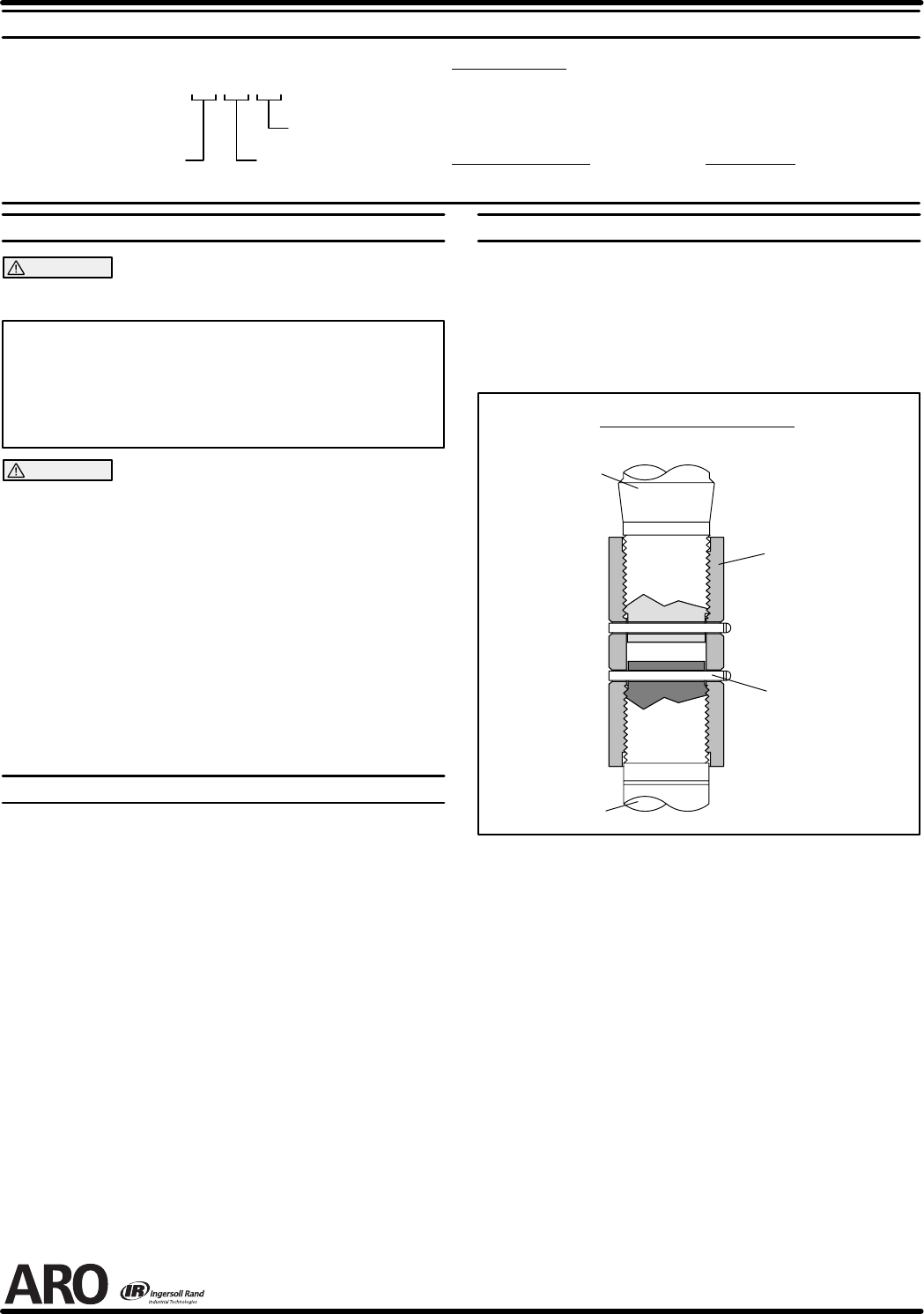

PUMP CONNECTION -- UPPER / LOWER

NOTE: All threads are right hand.

1. Lay the pump assembly on a workbench.

2. Remove the three nuts from the three spacer rods (figure 1).

3. Pulltheair motorfromthelower pumpend untilmotorpistonrod isin

the ‘‘down” position and lower pump end rod is in ‘‘up” position.

4. Removethecotterpinsandunthreadpistonrodsfromtheconnector

(figure 2).

Lower Pump

Piston Rod

Pump Motor

Piston Rod

CONNECTOR

92226

COTTER PIN

Y15-46-C (2)

PUMP CONNECTOR DETAIL

FIGURE 2

REASSEMBLY

1. Threadtheconnectortothepumpmotorpistonroduntiltheholethru

the connector is aligned with the hole thru the piston rod.

2. Assemble the cotter pin thru the hole and bend the ends of the pin

into the groove of the connector.

3. Threadtheconnectorto thelowerpumppistonrod untiltheholethru

the connector is aligned with the hole thru the piston rod.

4. Assemble the cotter pin thru the hole and bend the ends of the pin

into the groove of the connector.

5. Note: Heads and ends of cotter pins must not extend more than

.125” beyond o.d. of connector.

6. Reinstall the spacer rods to the pump motor.

7. Bring the motor and lower pump together and retain with the three

nuts.

PN 97999-834