HQ-006 I&M Manual HQ-402-0606 5

6.0 Electrical Connection

Move valve to mid-position by override nut. This will allow sufficient time to stop actuator in case of

improper hook-up

Identify means of removing power during hook-up

Be sure no erroneous remote control signals can be received causing actuator to energize

Electrically operate the valve in the open direction. If the valve closes, actuator must be stopped and

checked for improper field wiring

Set all field conduit entries in accordance with National Electric Code Requirements

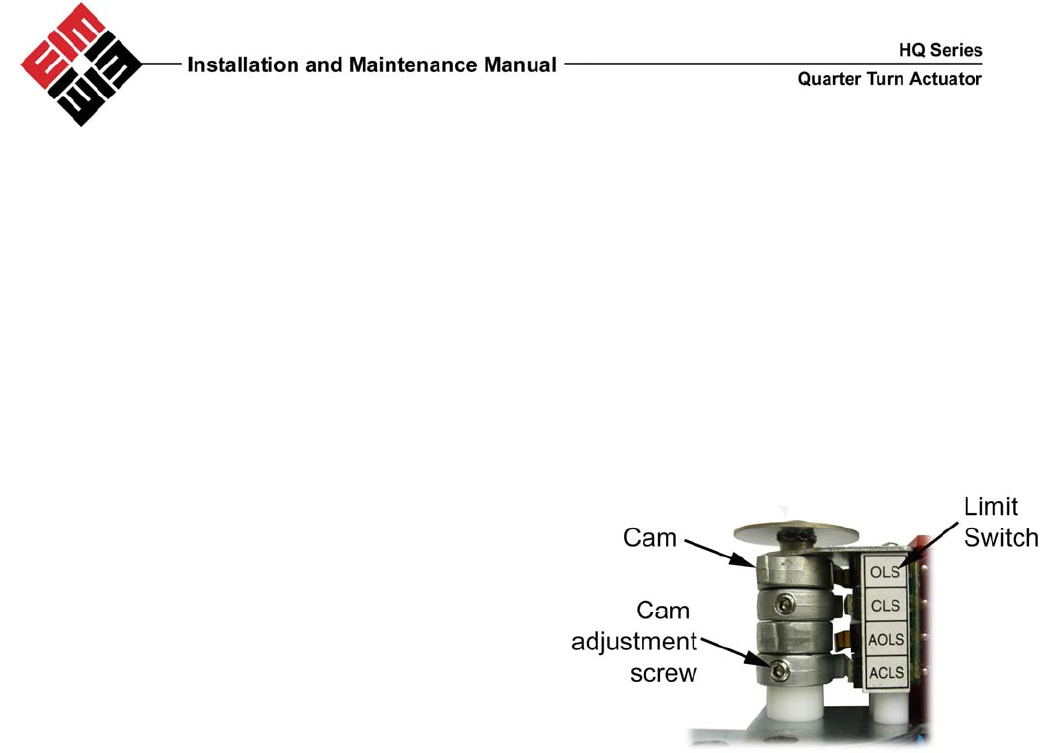

7.0 Limit Switch Setting Instructions

• Operate the actuator manually to closed

position

• Using a hex wrench, loosen the cam adjustment

screw in the CLS limit switch cam

• Rotate the CLS cam towards limit switch lever

until the switch ‘clicks’

• Tighten set screw with hex wrench

• Operated the actuator manually to open position

• Using a hex wrench, loosen the cam adjustment

screw in the OLS limit switch cam

• Rotate the OLS can towards limit switch lever

until the switch ‘clicks’

• Tighten set screw with hex wrench

• Repeat for AOLS and ACLS

8.0 Lubrication

The HQ series actuators are totally enclosed units with a permanently lubricated gear trains (Moly EP

Grease). Once installed lubrication should not be required. However, periodic preventative maintenance

will extend the operating life of the actuator.

9.0 MDPI Settings

Manually rotate actuator to fully closed position

Remove actuator cover

Loosen indicator screw

Adjust indicator to correct orientation

Tighten indicator screw

Replace cover

Check indicator alignment