ML6195, ML6295 SPRING RETURN DIRECT COUPLED ACTUATORS

63-2537—1

4

CAUTION

Deteriorating vapors and acid fumes

can damage the actuator.

Install actuator in areas free of acid fumes and other

deteriorating vapors that can attack the metal parts of

the actuator.

Location

Install the actuator in a location that allows enough clearance

for mounting accessories and for servicing.

Refer to Warnings and Cautions (above) for locations to avoid.

Mounting

The ML6195/ML6295 DCA has a self-centering shaft coupling

to accommodate specific shaft lengths, sizes, and shapes.

Proper actuator location and means of actuator rotation preven-

tion are necessary to avoid excessive strain on the output gear.

The ML6195/ML6295 DCA operates a damper or hydronic

valve by driving the shaft either cw or ccw, depending on the

design. All actuators are shipped with a 5° preload on the

spring. When power is applied to the actuator, the preload is

released and the actuator spring-returns 5° for tight closeoff.

The ML6195/ML6295 DCA is designed for single-point

mounting. Single-point mounting is typically used when the

actuator is mounted on a damper frame. A mounting bracket

(see Fig. 1) is provided for installing the actuator.

CAUTION

Avoid damage to the damper or actuator.

Do not allow the mounting bracket to bind or clamp

the actuator to the duct.

Use the mounting bracket only to prevent the actuator

housing from rotating.

Preparation

Before installing the ML6195/ML6295 on the shaft, determine

the opening direction of the damper or valve for correct spring

return rotation and wiring connections. The ML6195/ML6295

can be mounted to provide clockwise or counterclockwise

spring return.

Determine appropriate mounting orientation

See Fig. 2 for mounting orientation.

Measure shaft length

If the shaft is less than three inches in length, the shaft coupling

must be located between the damper/valve and actuator

housing. If the shaft length is more than three inches, the shaft

coupling may be located on either side of the actuator housing.

If the coupling must be moved from one side of the actuator

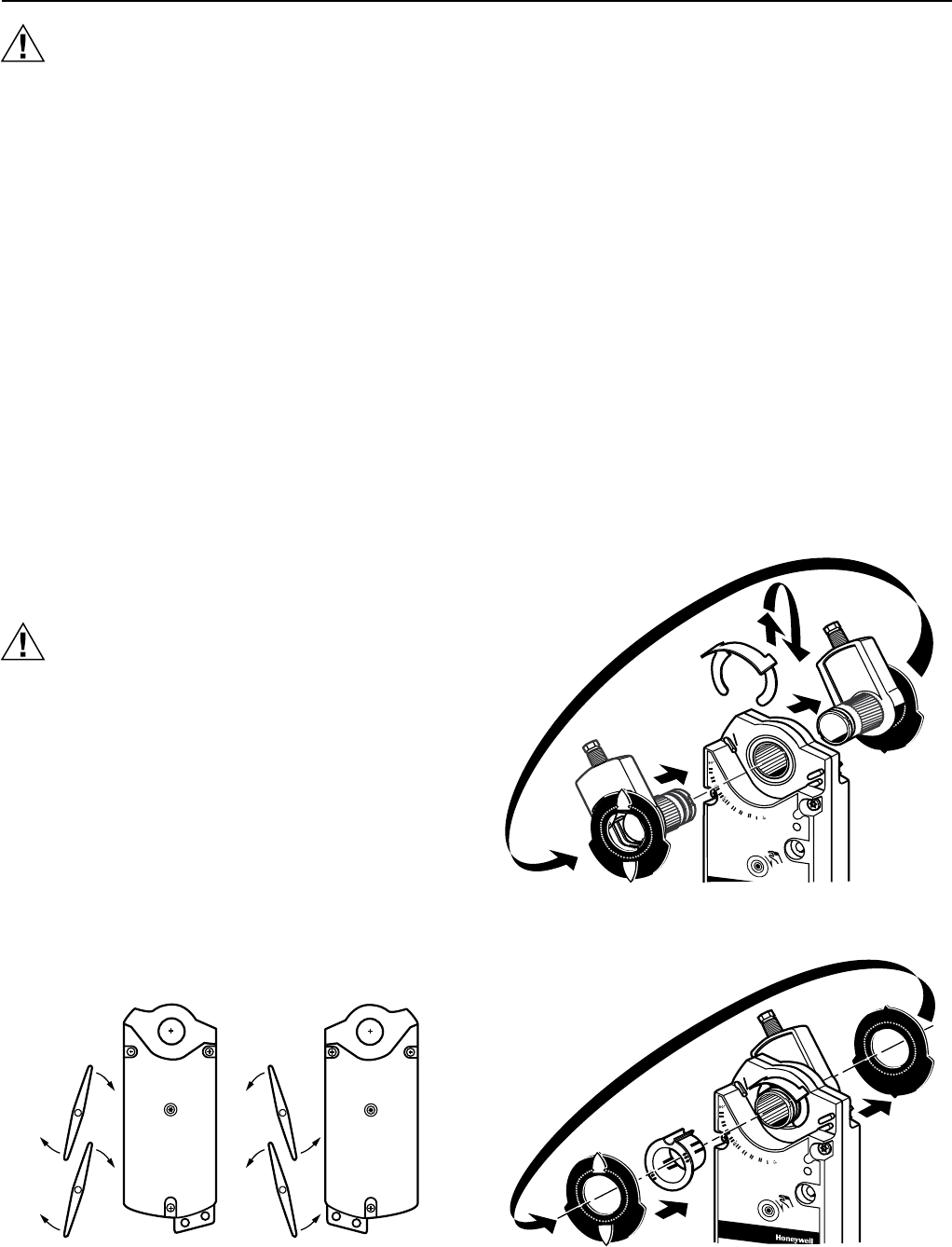

to the reverse, follow these instructions (see Fig. 3):

1. Remove the position indicator from the shaft coupling

and set it aside for later use.

2. Remove the retainer clip from the shaft coupling and

set it aside for later use.

3. Remove the shaft coupling from one side of the actuator.

4. Replace the shaft coupling on the opposite side of the

actuator aligning it with the mark on the housing.

5. Replace the retainer clip on the shaft coupling using the

inner groove of the coupling.

6. Replace the position indicator on the shaft coupling.

If the shaft coupling is located between the actuator housing

and damper/valve, the position indicator holder must be

attached to the other side of the actuator. If this is necessary,

perform the following (see Fig 4):

1. Slide the position indicator holder onto the shaft

coupling near the retainer clip and rotate it until it snaps

into place.

2. Place the position indicator on the holder.

CW TO OPEN

CCW TO CLOSE

(FAIL-SAFE

POSITION)

CW TO CLOSE

(FAIL-SAFE

POSITION)

CCW TO OPEN

M12443

Fig. 2. ML6195/ML6295 Spring Return Direct Coupled

Actuator mounting orientation.

Fig. 3. Mounting shaft coupling to opposite side of actuator.

M12441

Fig. 4. Adding position indicator holder.

M12440