XL-FW1114-01 Rev. A 7

3. Maintenance Procedures (continued)

3.2 Required Inspections and Adjustments (continued)

N

OTE:

P

erform the following every three (3) months or 50,000 km, whichever comes first.

T

horoughly steam clean all components before inspecting or adjusting.

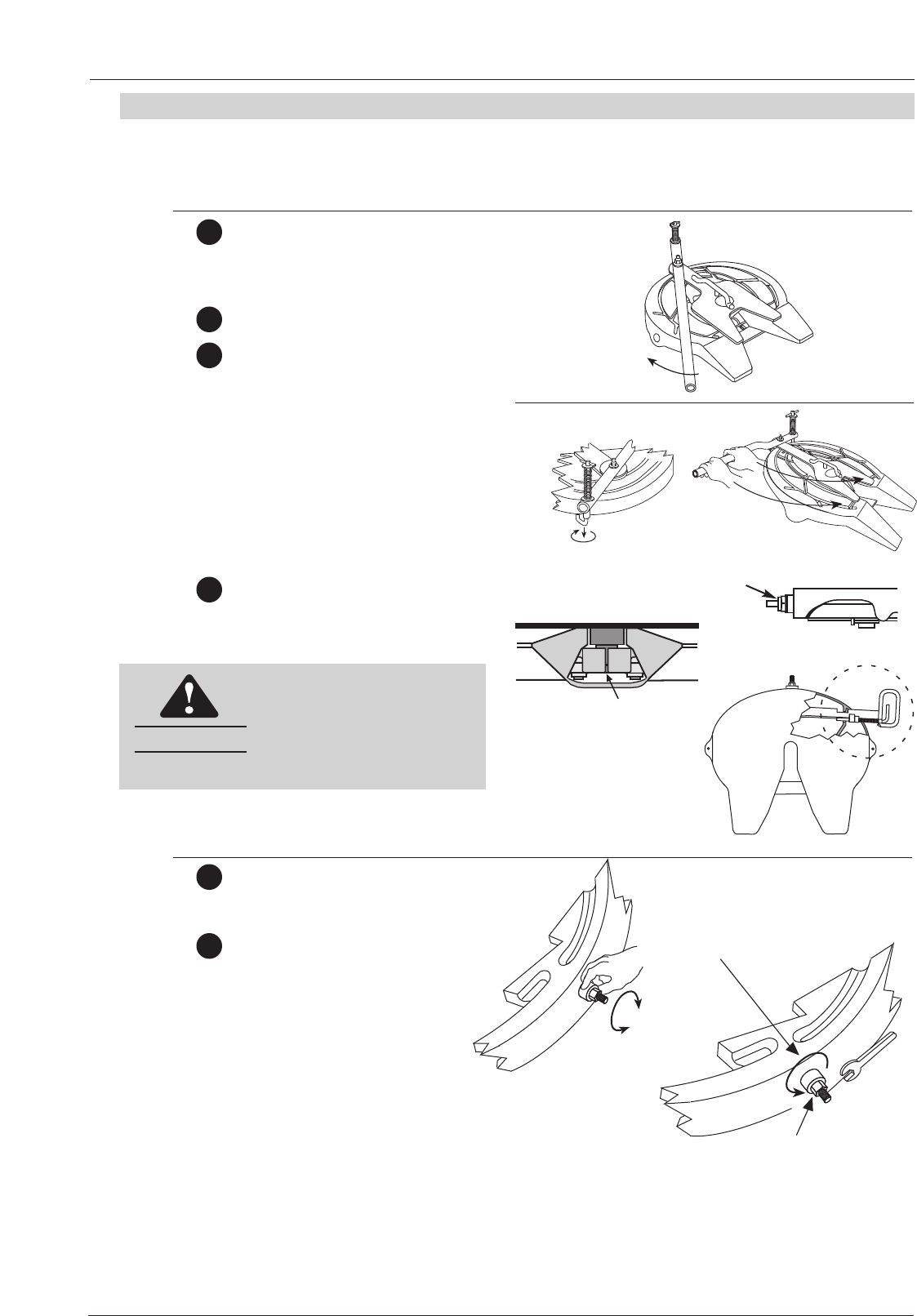

3.2.2 Inspection of Locking Mechanism

V

erify the proper operation of the

fifth wheel by locking and unlocking

the fifth wheel locks using a Holland

Kingpin Lock Tester TF-TLN-1000

or TF-TLN-5001.

S

et tool on the fifth wheel and rotate

the handle.

Push down and rotate the “J” hook

under the fifth wheel, then pull the

handle back.

After each attempt, verify that the

fifth wheel is properly locked, as

shown below.

3.2.3

Lock Adjustment Procedure

Close the locks using a Holland Lock

T

ester

, and r

otate the r

ubber bushing

between the adjustment nut and

the casting.

If the bushing is tight, rotate the

adjustment nut counter-clockwise

until the bushing is snug, but can

still be rotated by hand.

1

2

1

2

3

4

TO LOCK

TO UNLOCK

Nut and bushing snug

against the fifth wheel

Locks completely closed

around the kingpin

Release handle notch

is locked in the casing

WARNING

If you do not obtain a

proper couple, repeat the

coupling sequence.

DO NOT use any fifth

wheel that fails to

operate properly.

Rotate counter-clockwise

to tighten

ADJUSTMENT NUT