Installation

3A1189G 7

Pump

For complete pump instructions refer to the pump

instruction manual included with your system.

• If necessary, change the orientation of the fluid inlet

and outlet ports on the pump. See pump instruction

manual for this procedure.

• Retorque bolts per specifications.

Air Line

Alpha letters included in the following instructions refer

to letters shown in Typical Installation examples (F

IG. 1 -

F

IG. 2, pages 4 - 5).

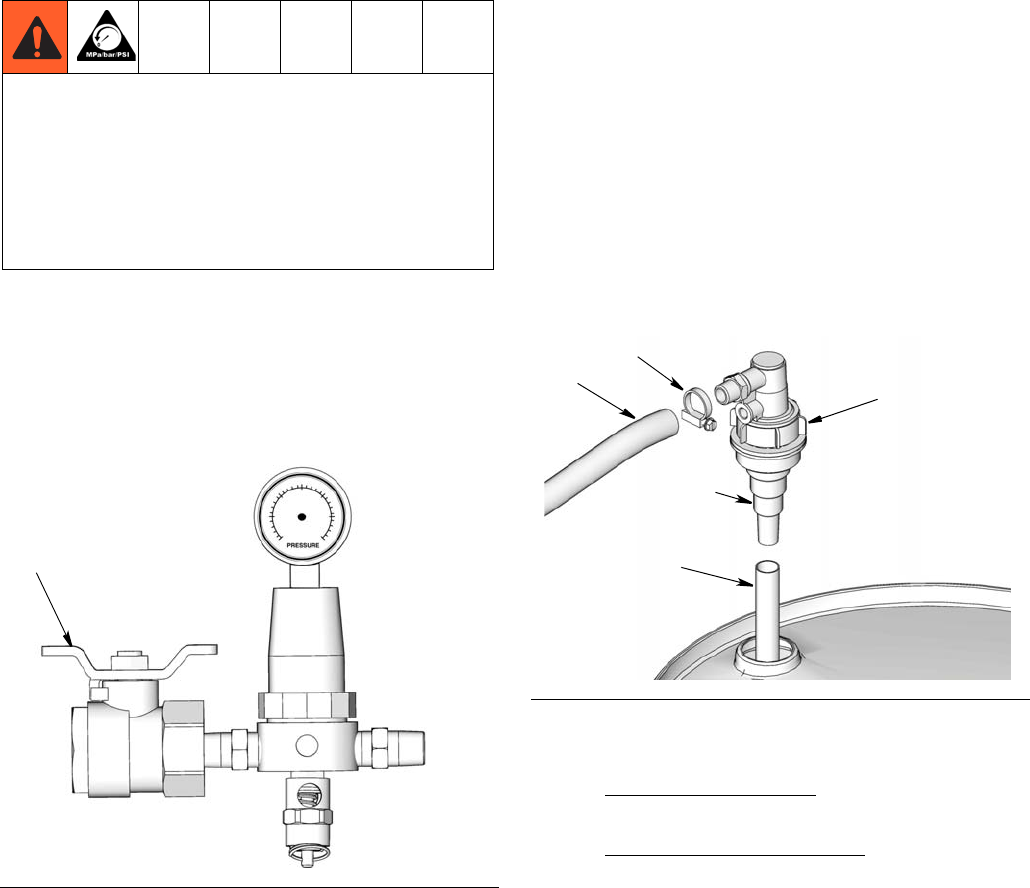

Locate one bleed-type master air valve (B) close to the

pump and use it to relieve trapped air (F

IG. 4). For drum

mounted installations only, also locate a second master

air valve upstream from all air line accessories and use

it to isolate them during cleaning and repair.

1. Using the hardware provided install the air controls

to the air inlet of the pump as shown in F

IG. 4. Use a

minimum 1/4 in. (6.3 mm) ID air hose.

2. Install an air line quick disconnect coupler onto the

end of the air supply line (C) and screw the matting

fitting into the pump air inlet snugly. Do not connect

the coupler to the fitting yet.

Fluid Supply Hose

Numerals used in the following instructions refer to ref-

erence numbers used in the Parts Lists provided on

pages 10 - 11.

1. Screw the fluid supply hose (9) fluid fitting into the

pump inlet snuggly. Do not overtighten.

NOTE: At the inlet, if the fluid pressure is greater than

15 psi (0.1 MPa, 1 bar) the diaphragm life will be short-

ened.

Fluid Suction Kit (6) - 24F532

Numerals used in the following instructions refer to ref-

erence numbers used in the Parts Lists provided on

pages 10 - 11.

The DEF System includes a Fluid Suction Kit containing

the following parts - Drum Coupler (6a), Drum Insert

(6b) and Suction Line (6c).

NOTE: The suction line (6c) can be used with either a

55 gallon drum or larger totes.

• If using with a large tote

: Do NOT trim the suc-

tion line.

• If using with a 55 gallon drum

: Trim the suction

line to 39 inches (991 mm). Remove all burrs.

A bleed-type master air valve (B) is required in your

system to relieve trapped air between the valve and

the pump. Trapped air can cause the pump to cycle

unexpectedly, which could result in serious injury

from fluid splashing in the eyes or on skin, injury

from moving parts or contamination from hazardous

fluids.

FIG. 4

B

FIG. 5

6c

6b

6a

E

F