Operation

308395D 7

Operation

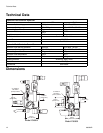

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

1. Close the supply line shutoff valve (G), and then

return line shutoff valve (E).

2. Hold open the dispensing valve to relieve pressure.

3. Place a container under the drain valve to catch any

drainage. Open the pump outlet drain valve.

4. Leave the drain valve open until you are ready to

pump again.

If you suspect that the dispensing valve nozzle or hose

is completely clogged, or that pressure has not been

fully relieved after following the steps above, VERY

SLOWLY loosen the hose end coupling and relieve pres-

sure gradually then loosen completely, now clear the

obstruction.

Emergency Stop Procedure

Close the red-marked supply line shutoff valve marked

STOP.

Before Starting the Pump

When starting up the hydraulic system, open the return

line shutoff valve (E) first.

Hydraulic Fluid Level Check

Check the hydraulic fluid level in the hydraulic power

supply before each use, and add fluid as necessary to

fill the lines.

Starting the Pump

• Never exceed 1500 psi (10.5 MPa, 105 bar) Maxi-

mum Hydraulic Pressure to the control.

• Never exceed 375 psi (2.6 MPa, 26 bar) Maximum

Outlet Pressure from the control when used with a

1/4:1 Dyna-Star

™

pump.

• Never exceed 1500 psi (10.5 MPa, 105 bar) Maxi-

mum Outlet Pressure from the control when used

with a 1:1 Power-Star

™

pump.

• Be sure all accessories added to the reciprocator

power supply side of the control are capable of at

least 1500 psi (10.5 MPa, 105 bar) maximum work-

ing pressure and all of those for the pump fluid out-

let side of the control have at least 375 psi (2.6 MPa,

26 bar) maximum working pressure for Dyna-Star

™

and 1500 psi (10.5 MPa, 105 bar) for Power-Star

™

.

1. Turn on hydraulic power supply.

2. Open the return line shutoff valve (E) first and slowly

open the hydraulic supply shutoff valve (G).

3. Remove the cap on the pressure reducing valve to

reveal the cap screw adjustment.

4. Adjust the hydraulic inlet pressure from 50 to 1500

psi (0.3 to 10.5 MPa, 3 to 105 bar) with an allen

wrench inserted in the regulator pressure control

adjustment on the pressure reducing valve (J).

Increasing the inlet pressure (clockwise) increases

the pump outlet pressure. Decreasing the inlet pres-

sure (counter clockwise) decreases the pump outlet

pressure.

5. Always use the lowest pressure possible to obtain

the desired results. This reduces pump wear.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.