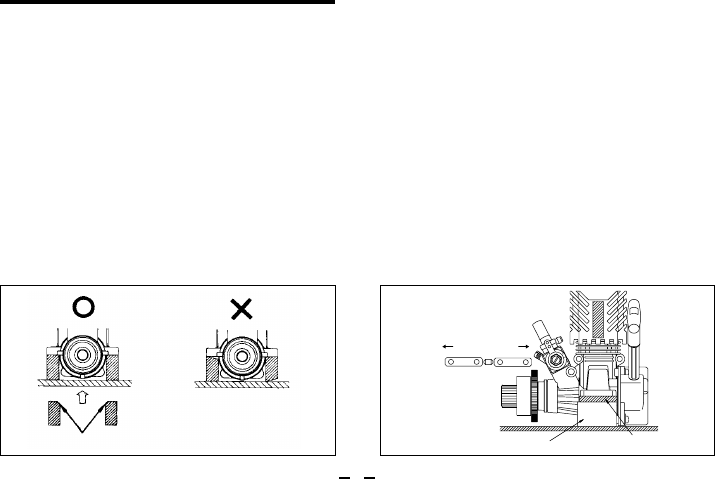

ENGINE INSTALLATION

Make sure that the vehicle's engine mounting

surfaces are level and in the same plane. Poor

installation may cause distortion of the

crankcase, bearings, etc., resulting in erratic

running and loss of performance.

The recommended screws for securing the

engine are 3mm or 4-40 steel Allen hexagon

socket type.

If existing holes in the engine mount do not align

perfectly with engine mounting lugs, enlarge

them slightly with a needle-file so that screws

enter vertically.

Chassis

Chamfer inside edges of bearers.

NOTE:

Where spacers are supplied joined in pairs

(see sketch) separate them as shown.

Either face may be placed downwards.

Avoid forcing the screws. Secure with locknuts.

If the bottom of the recoil starter housing would

otherwise touch the car chassis, fit the engine

mount spacers (supplied) between the engine's

mounting lugs and the engine mount. Use the

M3x15 screws provided. With some vehicles, it

may be necessary to make minor trimming

modifications to chassis or body when fitting the

engine.

Mount Spacer

Engine Mount Spacer

Separate

Engine Mount

7