'-""

"-"

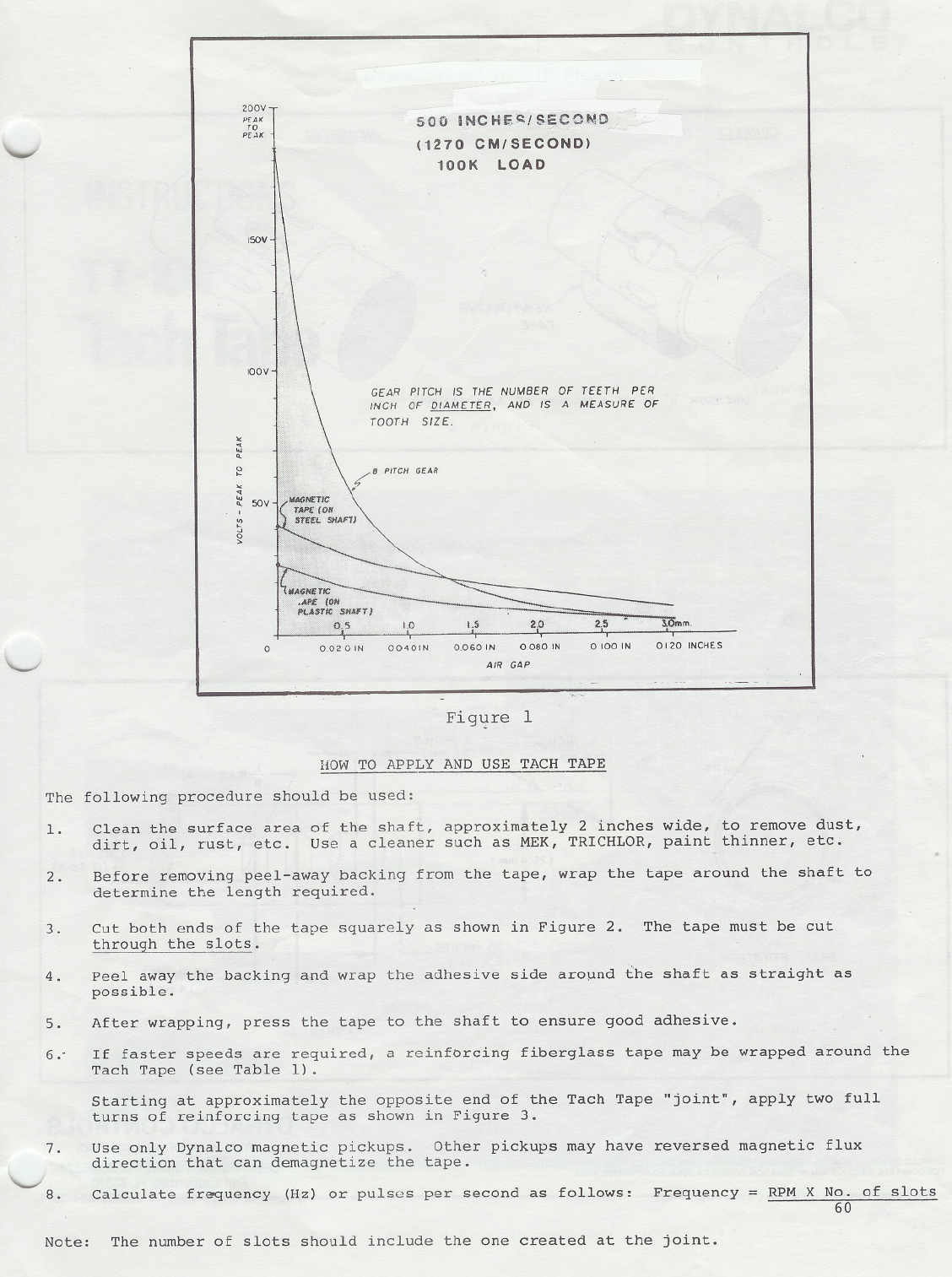

200V

PfAK

ro

PfOK

500 INCHE~!5ECOND

~ ~

(1270 CM/SECOND)

100K LOAD

I50V

100V

0.120 INCHES

GEAR PITCH IS THE NUMBER OF TEETH PER

INCH OF DIAMETER, AND IS A MEASURE OF

TOOTH SIZE.

"

"

'"

..

2

"

"

~

5OV

,

'"

~

0

~

~.5

'"r

10

m

..,

0

0.020 IN 0040 IN

0.060 IN

0060 IN

0 100 IN

AIR GAP

Fi gl.}re 1

amv TO APPLY AND USE TACH TAPE

The following procedure should be used:

4.

'-"

8.

Note:

1. Clean the surface area of the shaft, approximately 2 inches wide, to remove dust,

dirt, oil, rust, etc. Use a cleaner such as MEK, TRICHLOR, paint thinner, etc.

2.

Before removing peel-away backing from the tape, wrap the tape around the shaft to

determine the length required.

3.

Cut both ends of the tape squarely as shown in Figure 2.

through the slots.

The tape must be cut

Peel away the backing and wrap the adhesive side aro~nd the shaft as straight as

possible.

5.

After wrapping, press the tape to the shaft to ensure good adhesive.

6."

If faster speeds are required, a reinfbrcing fiberglass tape may be wrapped around the

Tach Tape (see Table 1).

Starting at approximately the opposite end of the Tach Tape "joint", apply two full

turns of reinforcing tape as shown in Figure 3.

7.

Use only Dynalco magnetic pickups. Other pickups may have reversed magnetic flux

direction that can demagnetize the tape.

Calculate frequency (Hz) or pulses per second as follows:

Frequency = RPM X No. of slots

60

The number of slots should include the one created at the joint.