Ignition unit

36 This comprises four elements (photo).

a) Power module - receives the ignition

advance command and controls the

conduction angle of the primary current

and energy stored in the coil.

b) Dissipater plate - eliminates the heat

which is generated by the high volume of

current.

c) Ignition coil with low primary resistance.

d) Distributor - a means of distributing high

tension to the spark plugs. The rotor is

driven in an anti-clockwise direction

(viewed from transmission) by a dog on

the end of the camshaft.

37 The system incorporates a safety

pressure switch, which cuts out the ignition if

the turbocharging pressure exceeds a value

of between 0.84 and 0.93 bars (12.2 and

13.5 lbf/in

2

) above atmospheric pressure.

Distributor (Microplex) -

removal and refitting #

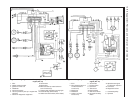

38 Remove the distributor cap and place it to

one side, complete with spark plug leads

(photo).

39 Turn the crankshaft by means of the

pulley nut, or by raising and turning a front

wheel with top gear engaged, until No. 4

piston is on its firing stroke. This will be

indicated when the contact end of the rotor

arm is aligned with the mark on the distributor

body rim, and the lug on the crankshaft pulley

is aligned with the timing pointer on the

engine. The right-hand underwing shield will

have to be removed in order to see the marks

(photo).

40 Unscrew the distributor fixing nuts and

withdraw the distributor.

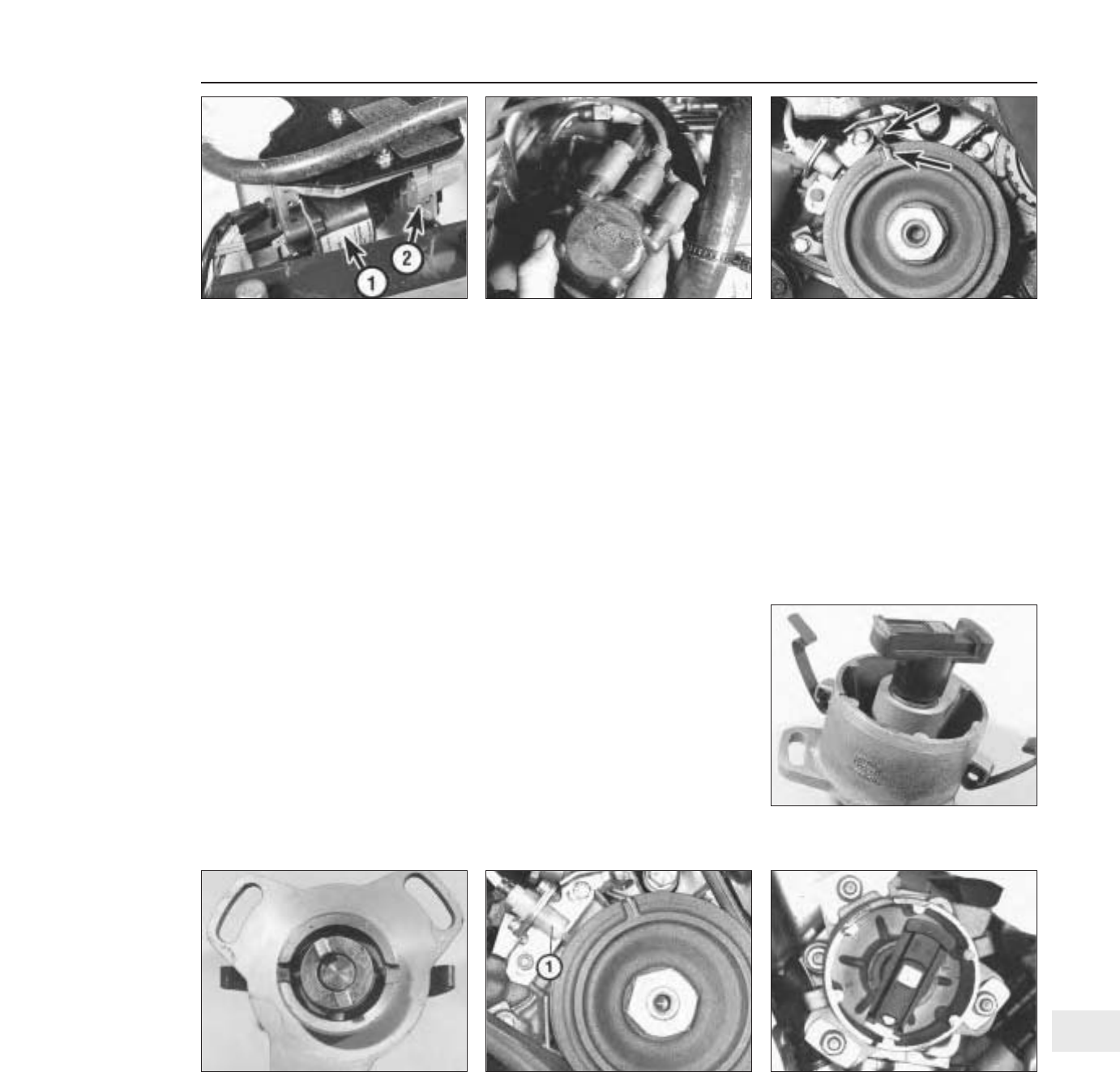

41 When fitting the distributor, the offset

drive dog will automatically locate the

distributor rotor in its correct position, but the

distributor body may require rotating in order

to align the rim mark with the rotor. The

elongated slots for the fixing studs are to

permit initial alignment, not for subsequent

adjustment, as advance angle alterations are

carried out automatically by the system ECU

(photos).

42 Tighten the nuts and refit the cap with

leads.

43 Unless a stroboscope and a vacuum

pressure gauge are available, it will not be

possible to check the advance values with the

engine running. Where these instruments are

available, connect the vacuum gauge to the

inlet manifold, and the stroboscope in

accordance with the equipment manufac-

turer’s instructions. Refer to Fig. 13.79

according to the inlet manifold vacuum

pressure indicated.

Microplex ignition system

components - testing ™

44 An ohmmeter and a voltmeter will be

required for these tests.

45 Remove the multipin plug from the ECU.

Engine speed sensor

46 Insert the probes of an ohmmeter

between terminals 3 and 16 of the multipin

connector; 618 to 748 ohms (1301 cc) or

578 to 782 ohms (1372 cc) should be

indicated.

47 If necessary, carry out a check of the gap

between the sensor and flywheel teeth as

described in Chapter 4, Section 10.

Supplement: Revisions and information on later models 13•89

10.39 Crankshaft pulley timing marks

(arrowed)

10.38 Removing the distributor cap10.36 Ignition coil (1) and power module (2)

on 1301 cc Turbo ie engine

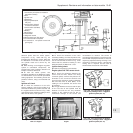

Fig. 13.78 Rotor aligned with distributor

body rim mark - Microplex ignition system

(Sec 10)

10.41A Distributor body showing elongated

slots in the mounting lugs

Fig. 13.77 Crankshaft pulley timing mark

aligned with timing pointer - Microplex

ignition system (Sec 10)

1 TDC sensor

10.41B Distributor drive dog

13