Page 2

©2003 Edelbrock Corp

Brochure #63-0025

Rev. 1/03

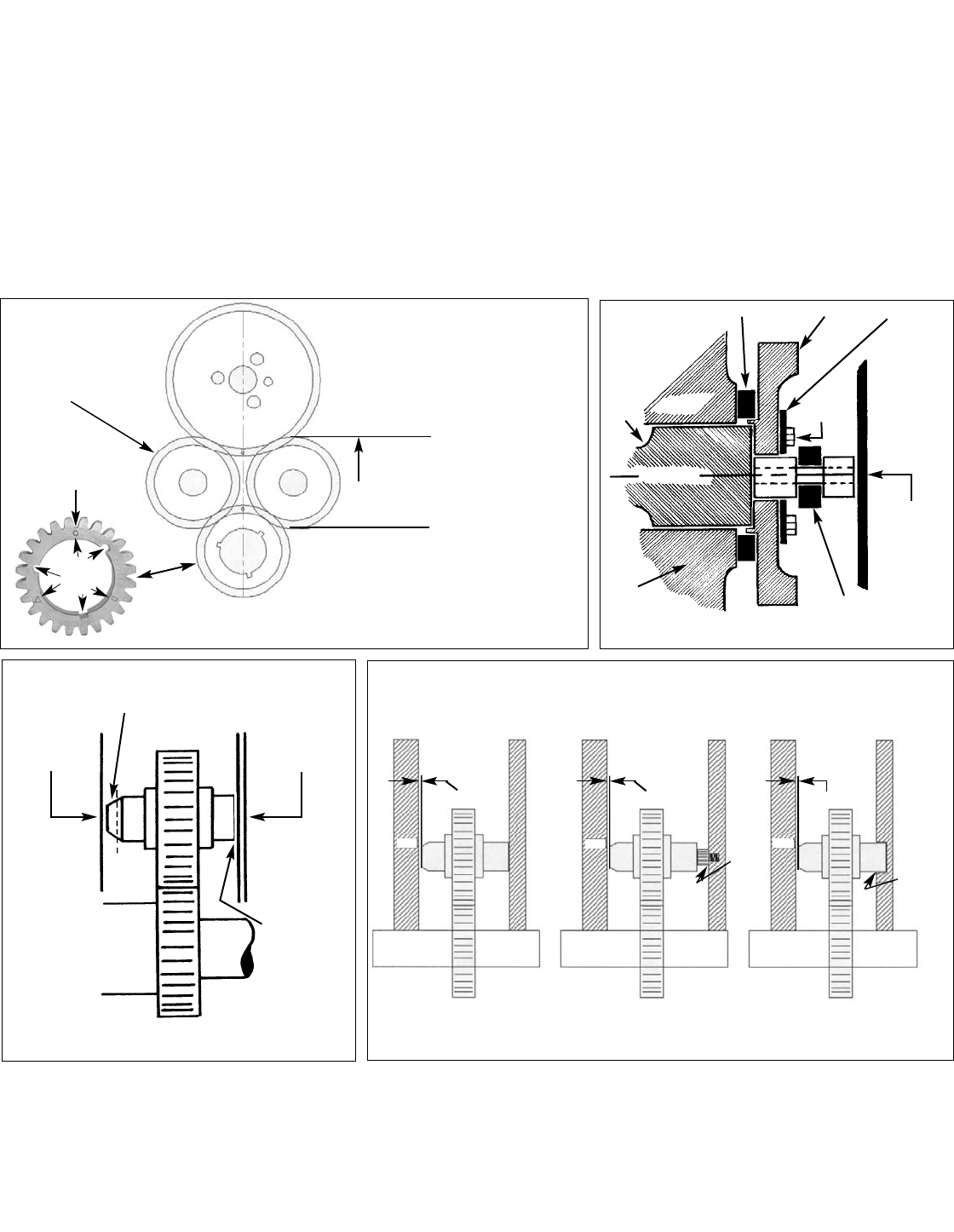

7 With the idler sub-assembly fully installed in mesh with crank and

cam gears and the large idler gear axle all the way back against the

block, check the clearance between end of idler axles and front

cover as follows:

(a) Place a small amount of clay on the front end of both axles as

shown in Figure 3.

(b) Install front cover with gasket in place and tighten cover bolts.

(c) Remove cover and measure the thickness of the compressed

clay. It should be .005"-.030".

(d) If axles are too long and are bottoming out between the block

and the front cover, you will need to grind off material from axles

as noted in Figure 3.

(e) Note: Non-stock timing covers may require special allen-type

screws be installed into the face of the cover to obtain the

correct thrust adjust ment for proper idler shaft clearance.

8. With all gears correctly in mesh and timed, tighten the three camshaft

capscrews to 20 ft./lbs. It would also be a good idea to use Locktite™

or equivalent on the bolt threads prior to final assembly.

9. Install the front thrust bearing assembly into the center hole of the

camshaft gear. Make sure that the bolt heads of the cam gear bolts do

not protrude farther than the nose of the thrust bearing; grind or file if

necessary.

10. Lubricate all gears and bearings with engine oil.

11. Re-install the front cover.

12. Re-install all components removed in preparation for step 1.

Edelbrock Corporation

2700 California Street

Torrance, CA 90503

Toll-Free Tech Line: 1-800-416-8628

Tech email: edelbrock@edelbrock.com

Line up Timing Marks on Shaft

centerline

Reverse idle (20 Teeth) should have

between .005-.070 free vertical

travel with power idler in hard

mesh with cam and crank gears

Power idler (23 teeth)

Figure 1

Figure 4

CrankshaftCrankshaftCrankshaft

.015 -.060 Clearance

Stock Front Cover

Standard Inside Depth

Aluminum Front Cover

Inside Depth more Than

Stock

Aluminum Front Cover

Inside Depth Less Than

Stock

.015 -.060 Clearance

.015 -.060 Clearance

Block

Block

Block

Install

Screw in

Front

Cover to

Touch

Idler

Pins

Mill Recess

in Front Cover

Brass Thrust Ring

Locking Plate

Cam

Block

Block

Crankshaft

Cam Gear

Front Thrust

Bearing Assembly

Capscrew

Timing Cover

Timing Cover

Remove material from

this end of axle.

Place clay in

this area to

check shaft

end clearance

Figure 2

Figure 3

Timing

Mark

A

O

R