page 3

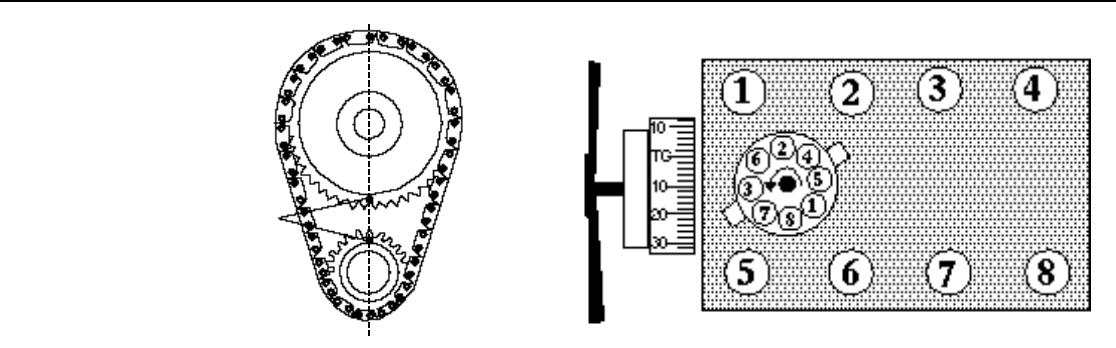

Firing Order 1-5-4-2-6-3-7-8

429/460 c.i.d. Ford V8

Turn distributor clockwise to advance timing.

• CAUTION: Use Edelbrock Performer-Link Timing Chain

and Gear Set #7830. Do not use late model timing chain and

gear sets that are designed for emission-controlled engines.

These timing sets are machined in a retarded position and are

not recommended for this camshaft installation. Edelbrock

Timing Sets feature three keyways for specific timing selec-

Figure 1

Timing Chain

Sprocket Alignment

Timing Marks

Figure 2

• CAMSHAFT/LIFTER RUN-IN

CAUTION: Change the engine oil and filter before start-up

and again after the initial break-in. Do not allow the engine to

run under 2000 rpm for the first 1/2 hour. Vary engine speed

between 2000 and 2500 rpm. Slow idle speeds may result in

severe cam and lifter wear.

1. Start the engine and bring to break-in rpm.

• IMPORTANT INSTRUCTIONS AFFECTING

YOUR WARRANTY

• CAM LOBE WEAR- Cam lobe wear is almost non-existent

unless mismatched parts are used or installation of the cam

and lifters is done improperly. Most cam damage is caused by

the timing gear coming loose due to improper torque on bolt.

Bolts holding gear to camshaft should be torqued carefully and

a locking compound applied to threads of bolts.

• CAM GEARS AND CAMSHAFT END PLAY- If cam gear

becomes loose, the cam will slide back in the block, causing

the lifters to hit the lobes next to them and also the cam bear-

ing journals. If the engine is run after this happens, the bottom

of the lifters and the sides of the lobes will become clipped.

When installing a camshaft, it is always important to check for

proper operating clearances, especially when high performance

components are used. Things to look for that can cause failure

and damaged parts are as follows:

1. Improper valve-to-piston clearance (this should be no less than

0.080").

2.

Rocker arm stud slot clearance (both ends; valve closed and open).

3. Proper spring settings (see dimensions with spring instruction

sheet; correct dimensions mean maximum performance and

longer engine life).

• SPECIAL INSTRUCTION

With the Edelbrock manifold and camshaft package plus a head-

er installation, a carburetor jet change may be required for best

performance. Due to the varied applications of year and model

of vehicles, no one combination could suffice for all installa-

tions. The following procedure is only a guideline and in many

cases, the manufacturing specifications for recommended carbu-

retors or timing may be best.

• IGNITION TIMING

Ignition timing for this package may vary with each application.

A good starting figure would be between 10 degrees to 14

degrees initial timing at idle with vacuum advance disconnected.

Total advance should not exceed 32 degrees to 34 degrees with

initial and centrifugal weights combined and should be at full

advance at 3000-3500 rpm. After timing is adjusted, re-connect

the vacuum advance line. NOTE: The best combination for any

particular vehicle or application must be determined by trial and

error using the above information as a guideline.

• HEADERS

For best performance, headers are recommended. For this appli-

cation, they should be 1-3/4" diameter, approximately 31"

long

and terminating into a 3" or 3-1/2" collector. The remainder of the

exhaust system should consist of dual exhaust and tail pipes, at least

2" diameter with low back-pressure mufflers.

• WARNING

In order for this Performer RPM cam and lifter kit to be covered

under ANY WARRANTY you MUST use the correct Edelbrock

Sure Seat Valve Springs. The end flap or label from your Sure

Seat Valve Spring box must be sent in with your camshaft war-

ranty card.

Failure to install new Edelbrock Sure Seat Valve Springs with

your new Performer RPM cam and lifter kit could cause the cam

lobes to wear excessively and could cause additional engine

damage. IF YOU HAVE ANY QUESTIONS ABOUT THIS

APPLICATION, PLEASE CONTACT OUR TECHNICAL

DEPARTMENT IMMEDIATELY.

•

PLEASE complete and mail your warranty card. Be sure to write

the model number of this product in the “Part #____” space..

THANK YOU.