4

Edelbrock Performer Series Carburetor Owner’s Manual 8/94

Fuel is drawn through the Idle System (Figure 2) by the intake manifold vacuum that is

communicated at the Idle Screw Port (8) and Transfer Slot (7). Fuel in the bowl passes through the

Primary Main Jet and Metering Rod Restriction (1) and into the Primary Well (2). The fuel for the Idle

System is drawn through the restriction at the end of the Idle Jet (3) - a brass tube - and flows up the

tube to the location of the 1st Idle Air Bleed (4) - a brass restrictor - where air is mixed with the liquid

fuel. The emulsified air and fuel is then drawn through the Idle Channel Restrictor (5) - a drilled passage

that serves to increase the velocity of the air and fuel to promote better mixing. As the emulsified fuel is

discharged from the Idle Channel Restrictor, additional air is added at the 2nd Idle Air Bleed (6) - a drilled

hole - and the highly aerated mixture then moves through the passages in the main-body to the location

of the Transfer Slot (7) and Idle Screw Port (8). The Transfer Slot (7) is a large air bleed when the throttle

is closed, but as the throttle is opened the slot is exposed to manifold vacuum and becomes a discharge

port for Idle System fuel. The Idle Screw Port is a variable discharge restriction that is adjusted by the

engine tuner to achieve the desired A/F Ratio at engine idle.

Primary Main System: The Primary Main system delivers an increasing percentage of the fuel as

throttle position increases (phasing over the Idle System) and varies fuel delivery in response to air flow

and manifold vacuum.

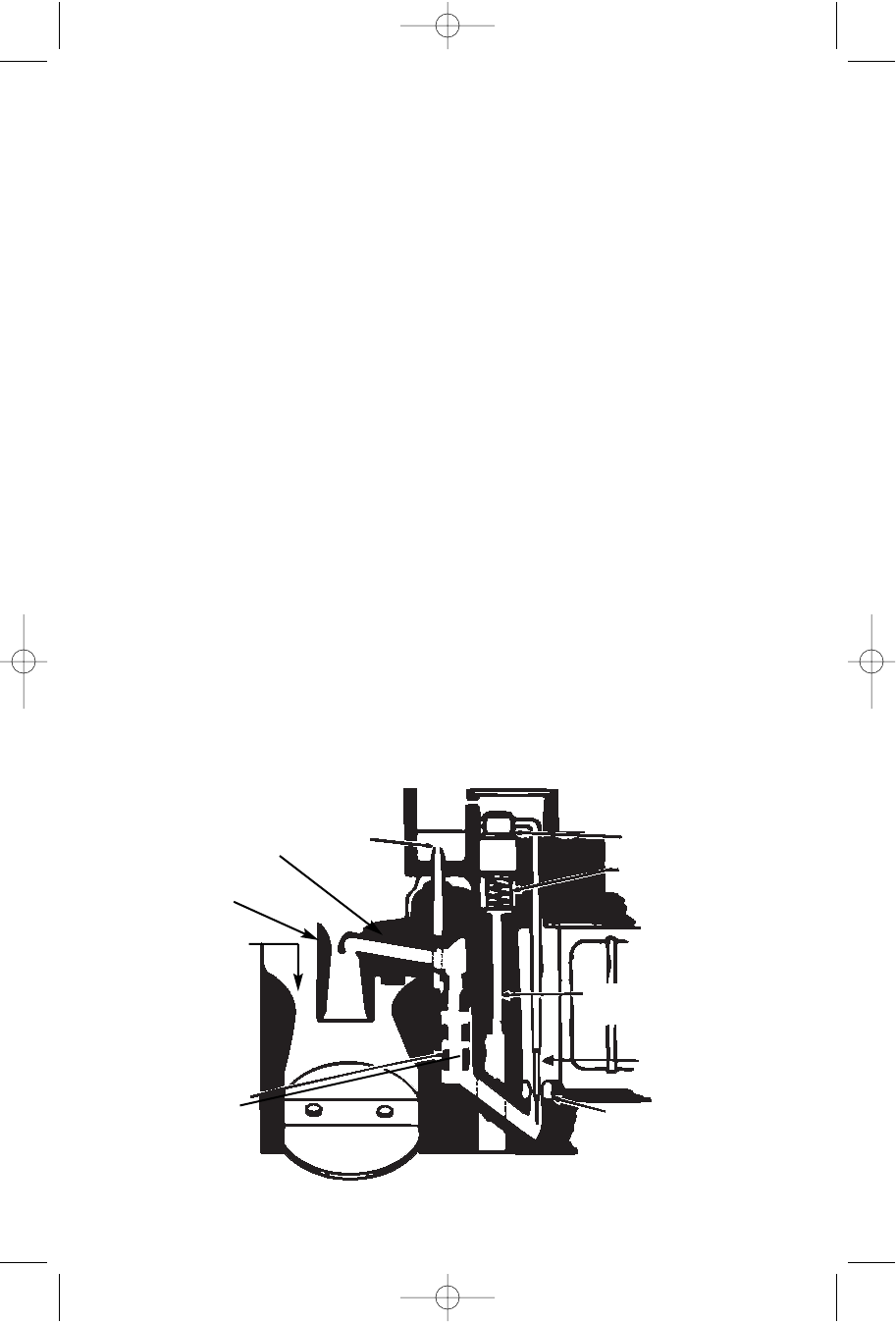

Fuel is drawn through the Main System (Figure 3) by the pressure-drop that occurs when the incoming

air flow must increase in velocity in order to pass the reduced throat areas at the Main Venturi (1) and the

Boost Venturi (2). This pressure-drop (or suction) is communicated to the system by the Nozzle (3)-a

brass tube that opens into the inside of the Booster Venturi (2).

The fuel must pass through the restriction at the Main Jet (4) and Metering Rod (5). The Rod extends

through the Jet, reducing the amount of area available for fuel flow. If the diameter of the Rod is large,

then fuel flow through the Jet is more restricted than if the Rod were small.

After the Rod and Jet, the fuel enters the Primary Well and is drawn up the inside of the Primary Well

Tube (6). Sometimes this tube is called an Emulsion Tube. Here, the fuel is mixed with air that enters the

inside of the Tube through a series of small holes. The air is supplied by the Main Well Bleed (7) at the

top of the Main Well. The air/fuel mixture exits from the top of the Main Well into a passage that leads it

to discharge into the Booster Venturi (2) at the Nozzle (3).

Primary Main

System

Figure 3

(6) Primary

Well

Tube

(1) Main

Venturi

(2) Boost

Venturi

(3) Nozzle

(7) Main

Well

Bleed

(9) Step-Up

Piston

(8) Vacuum

Passage

(5) Metering Rod

(4) Main Jet (primary)

(10) Step-Up

Piston Spring

1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:04 PM Page 4