LUBRICATION INSTRUCTIONS

OPERATION IN PRESENCE OF DUST, WATER

OR CORROSION VAPORS

This bearing is factory lubricated with No. 2 consistency

lithium complex base grease which is suitable for most

applications. However, extra protection is necessary if

bearing is subjected to excessive moisture, dust, or

corrosive vapor. In these cases, bearing should contain as

much grease as speed will permit (a full bearing with

consequent slight leakage through the seal is the best

protection against contaminant entry).

In extremely dirty environments, the bearing should be

purged daily to flush out contaminants. For added protection,

it is advisable to shroud the bearing from falling material.

HIGH SPEED OPERATION

At higher operation speeds, too much grease may cause

overheating. In these cases, the amount of lubrication can

only be determined by experience. If excess grease causes

overheating, remove grease fittings and run for ten minutes.

This will allow excess grease to escape. Then wipe off

excess grease and replace grease fittings.

In higher speed applications, a small amount of grease at

frequent intervals is preferable to a large amount at

infrequent intervals. However, the proper volume and

interval of lubrication can best be determined by experience.

AVERAGE OPERATIONS

The following table is a general guide for normal operating

conditions. However, some situations may require a change

in lubricating periods as dictated by experience. If the

bearing is exposed to unusual operating conditions, consult

a reputable grease manufacturer.

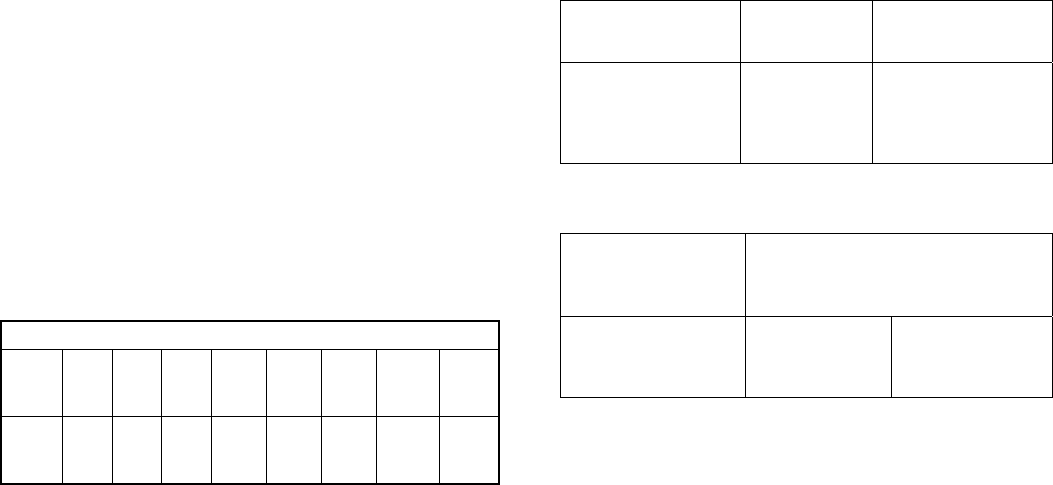

Lubrication Guide

Read Preceding Paragraphs Before Establishing Lubrication Schedule

Suggested Lubrication Period in Weeks

Hours

run

per day

1 to

250

rpm

251 to

500

rpm

501 to

750

rpm

751 to

1000

rpm

1001 to

1500

rpm

1501 to

2000

rpm

2001 to

2500

rpm

2501 to

3000

rpm

8

16

24

12

12

10

12

7

5

10

5

3

7

4

2

5

2

1

4

2

1

3

2

1

2

1

1

OPERATING TEMPERATURE

Abnormal bearing temperatures may indicate insufficient

lubrication. If the housing is too hot to touch for more than a

few seconds, check the temperature by applying a thermom-

eter at the top of the pillow block with the thermometer tip

surrounded by putty.

Because the thermometer reading will be approximately

10°F lower than the actual bearing temperature, add ten

degrees to the reading and compare to the temperature

rating of your grease. If the bearing temperature reading is

consistent and operating within the recommended limits of

your grease, the bearing is operating satisfactorily.

The recommended maximum operating temperature for S-

2000 Spherical Roller Bearings is 200 °F.

STORAGE OR SPECIAL SHUT DOWN

If equipment will be idle for some time, before shutting down,

add grease to the bearing until grease purges from the

seals. This will ensure protection of the bearing, particularly

when exposed to severe environmental conditions. After

storage or idle period, add fresh grease to the bearing before

starting.

SET SCREW TORQUE TABLE

Shaft Size

Socket

Set Screw

Size

Tightening

Torque

13/8 - 13/4 inches

11

15/16 - 27/16 inches

12

11/16 - 37/16 inches

13

15/16 - 415/16 inches

5/16 inches

3/8 inches

1/2 inches

5/8 inches

165 Inch Pounds

290 Inch Pounds

620 Inch Pounds

1325 Inch Pounds

RECOMMENDED SHAFT TOLERANCE TABLE

Low to Normal Equivalent

Normal Load and Catalog

Shaft Size Speed*

Up to 11/2 inches +.000 inches –.0005 inches

Over 11/2 to 21/2 inches +.000 inches –.001 inches

Over 21/2 to 4 inches +.000 inches –.001 inches

Over 4 to 5 inches +.000 inches –.0015 inches

On severe applications and where dynamic balance and minimum

runout are important, a snug to light press fit may be required to

obtain optimum bearing performance. Consult factory.

*Normal equivalent load .08C to .18C.