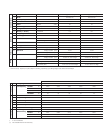

Standard Equipment

1. Crown’s Access 1 2 3

®

Comprehensive System Control

2. Crown’s AC traction

control system

3. 24-volt electrical system

4. Electronic steering

5. Linear Height Speed Contol

6. High-speed lift (SP 3520 and

SP 3550H)

7. Two-speed lower with soft

start and stop

8. Programmable lift/lower

cut outs

9. Intelligent Braking System (IBS)

with low-profile brake pedal

10. Crown Display

• Battery discharge indicator

with lift interrupt

• Hour meters/travel

distance/stop watch

• PIN code access capable

• Access 1 2 3 diagnostics

• P1, P2, P3 Performance

• Standard steer tire

direction indicator

(non wire-guided trucks)

• Enhanced steer tire

direction indicator

(wire-guided trucks)

11. Lift motor brush wear and

overtemp indicator (SP 3550H).

12. Soft urethane twist grip

with “cam grip”

13. 10° angled steer wheel with

soft feel spinner

14. Storage compartment

15. Premium platform cushion

16. Clear visibility platform

window

17. Clear visibility mast design

18. Key switch

19. Horn

20. Strobe light, amber

21. Hinged side gates with

power disconnect

22. 14.25" battery compartment

(13.12" on SP 3505)

23. 350 amp battery connector

(175 amp on SP 3505)

24. 2" diameter battery

compartment rollers

25. Top battery access for service

26. Removable steel battery

side covers

27. Adjustable battery retainer

28. Hinged, lift off steel power

unit doors

29. Emergency power cut-out

30. Operator belt and lanyard

Operator Platform

The operator area is designed for

maximum visibility and stability for

increased operator confidence

and comfort.

The operator platform features

a large window (1088 sq in) for

excellent visibility. A Crown-

designed clear-visibility mast

affords the platform window one

forward and two peripheral win-

dows for maximum visibility, even

when the platform is lowered.

The clear-visibility mast, with

full free lift, extends the platform

window above the mast

channels for unobstructed

visibility when raised.

A low-profile power unit, low

placement of the lower cross

brace and an outer C-channel

rail assembly also contribute to

excellent visibility.

A soft urethane twist grip is solidly

mounted to the truck console to

provide excellent stability for the

operator during travel, plugging

and braking. Controls for lift/lower,

horn and emergency disconnect

are conveniently located for

efficient operation and minimal

operator fatigue. The steering

wheel is angled at 10° and

recessed to maximize the work

area and reduce steer effort. The

steering wheel and spinner knob

are covered with soft urethane to

reduce grip force and insulate

against vibration. Control location

keeps the operator’s posture

neutral at all times.

The platform cushion, made of

a microcellular composition,

absorbs shock and vibration.

The brake pedal has a low-profile

design and when engaged is flush

with the platform cushion for

maximum comfort. Heavy-duty

side gates, with two horizontal

and one vertical support rails,

communicate security to the

operator. For additional safety,

cut-out switches disengage

truck operation when side gates

are raised.

Two work lights, two dome lights

and a two-speed fan are optional.

“Power-on” key prevents unau-

thorized operation of the truck.

The Access 1 2 3 Display Panel

provides concise, clear feedback

for the operator during truck

operation.

31. Pallet clamp

32. InfoPoint

®

Quick Reference

Guide and Maps

33. Color-coded wiring

34. 6" diameter tandem

load wheels

Optional Equipment

1. Crown wire guidance

(broadband technology)

operates on all frequencies

ranging from 5.2 through

10 Khz without changing

components.

2. End of Aisle Control System

(wire or rail guidance required)

3. Aisle guide wheels for

rail guidance

4. Lift motor brush wear and

overtemp indicator (SP 3520).

5. Enhanced steer tire

direction indicator

(non-wire guided trucks)

6. Battery retainer

interlock switch

7. Work lights, dome light

and two-speed fan

8. Spotlights

9. Flashing light, amber

10. Programmable lift/lower

cutouts with over-rides.

11. Zone select key switch

12. 48", 54", and 60" wide

operator platforms

13. Corrosion conditioning

14. Freezer conditioning

(Includes corrosion condi-

tioning, ribbed floor mat,

and wire mesh windshield)

15. EE Rating available on

SP 3520 and SP 3550H

16. Wire mesh screen (Standard

with freezer conditioning)

17. Retractable tether

18. Load wheel and drive

tire compounds

19. 30" lanyard boom

20. InfoLink™ Ready

21. Positive / negative

accessory cable

22. Special paint

23. Work Assist™ Accessories

• Clip pad and hook

• Plate

• Pocket

24. Fire extinguisher

Crown’s Access 1 2 3...

The Comprehensive Access 1 2 3

System Control is a modular

based communications and

control system. It monitors all

on-board sensors, makes

decisions based on the sensor

readings, and subsequently, con-

trols all system movements safely

and smoothly. All five modules are

in constant communications with

each other via a CAN (Control

Area Network) bus so that real

information is accessible to the

system at all times.

• Interactive Display Module

• Traction Control Module

• Vehicle Control Module

• Steering Control Module

• Guidance Control Module

Crown Drive System

Crown has applied the latest

generation AC drive system,

enhanced with Access 1 2 3

technology. A Crown-manufac-

tured drive unit uses spiral bevel

and helical gears from motor to

drive wheel axle.

Fixed, mounted drive motor does

not rotate minimizing wear on

electricall cables. Drive tire

changing is simplified with this

drive unit.

Crown’s AC Drive system dra-

matically improves travel speeds,

acceleration and deceleration,

thus increasing productivity.

The standard linear speed control

provides smooth travel speed

transition as lift heights change

and increases productivity.

SP 3500 Series

Technical Information