A

A

B

DD

CC

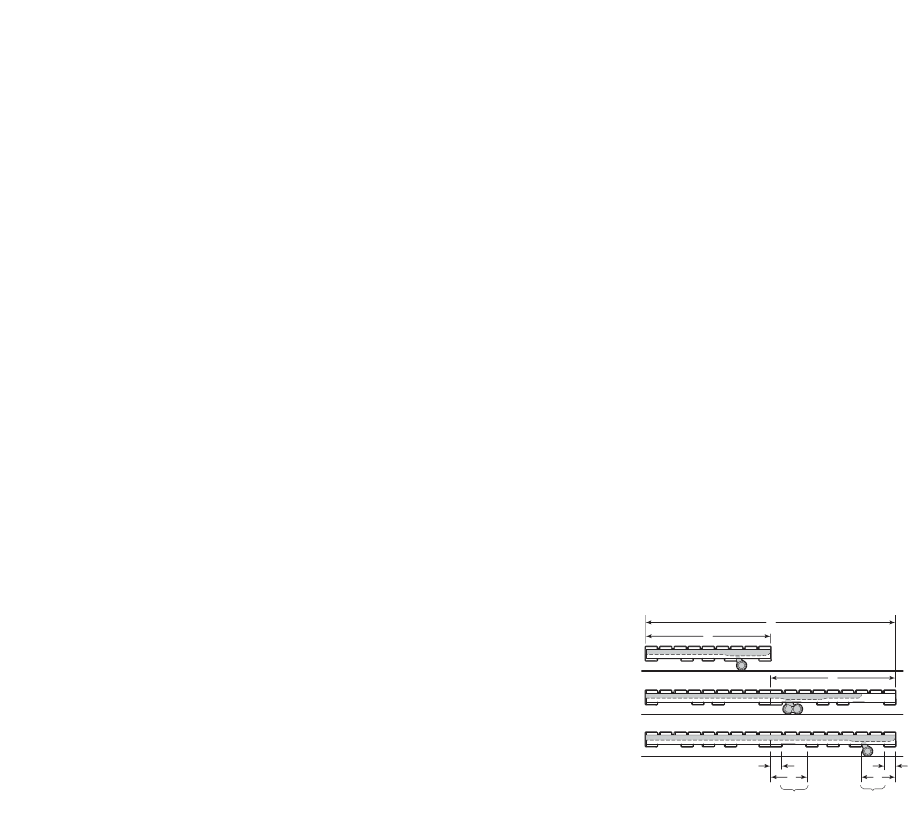

First

Opening

Second

Opening

PR 4500 Series

Technical Information

Fork Assembly

Fork width - 9.12" on standard-tip

fork models, 10" on extended-tip

fork models. Fork spread - 22"

and 27" on standard-tip models.

23" - 26" spread available in one

inch increments. 23" and 28"

standard on extended-tip models.

Fork spreads from 24"-27" avail-

able in one-inch increments.

Fork lengths - 36", 42", 48", 54",

60", 96" with standard-tip; 84",

93", and 96" forks available with

extended-tip design for shorter

wheelbase.

To facilitate pallet entry/exit

Crown has engineered several

features into their fork assembly.

Standard-tip forks have pallet

entry rollers to lift fork over

bottom board of pallet. Rollers

are made of high molecular

weight polyethylene with .75"

axle and roll pin.

Extended-tip fork design has

totally enclosed tip with full length

convex bottom surface creating

an entry ramp. Ramp design

helps fork glide over bottom

boards of pallet and keeps welded

edges from touching boards

of pallet.

Abrasion resistant steel entry/exit

slides on both sides of each fork

which have convex bottom

surfaces to prevent snagging as

forks move over bottom boards

of pallet. One piece design with

radial edges are welded away

from contact point of slide.

Exit roller design prevents load

wheel from dropping after cross-

ing bottom board. The 3" wide,

steel exit roller is positioned

directly behind the load wheel

to keep the fork rolling. Entry/exit

slide design also assists in

trouble-free pallet entry/exit.

Fork adjustability is done at the

toe with no need to remove a

cover plate. Fork heel height ad-

justment is done quickly without

removing battery. Quick and

easy fork adjustment promotes

servicing of fork assembly to

keep pallet entry/exit productive.

Pull rod design incorporates

a replaceable “tenon” for fast

servicing of pull rod while still in

the truck. Damage related to

impacts is limited to the replaceable

“tenon”, not the entire pull rod.

Power Unit Structure

Heavy gage steel is used in the

platform and power unit skirt with

additional steel reinforcement

where needed.

The power unit door and motor

cover also utilize heavy steel for

protection of critical components

and long term durability. The

power unit door swings out for

easy access to components.

e-GEN™ Braking System

Variable regenerative motor

braking is optimized and virtually

eliminates brake maintenance.

When the truck is traveling, if

the operator releases the brake

pedal, removes travel input

request or reverses direction

e-GEN braking is applied.

The closed loop Access 1 2 3

traction control will keep the

truck static until a travel input is

requested, even when operating

on a grade.

Automatic electric parking brake

activates when the operator

releases the brake pedal and the

truck has been stationary for four

seconds, the truck is keyed off,

or the battery has been

disconnected.

Pallet Planning Guide

On standard-tip fork models, the

load wheel will drop in the second

opening of the pallet when “A” or

“B” dimension equals the nominal

fork length. On extended-tip fork

models, the load wheel will drop

in the first opening of the second

pallet. On models with a single

load wheel, the “C” dimension

should be 6" maximum and the

“D” dimension should be 14"

minimum. On models with tandem

load wheels, the “C” dimension

should be 6" maximum and the

“D” dimension should be 17"

minimum. Customers that need

tandem load wheel trucks, but

use pallets with smaller openings,

may be accommodated if the

maximum lift height of the truck

is reduced. Contact your local

Crown dealer for details.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with audible

travel alarms and flashing lights

include:

• Multiple alarms and/or lights

can cause confusion.

• Workers may ignore the

alarms and/or lights after

day-in and day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and

the conditions of the operating

area. Crown products and

specifications are subject to

change without notice.