9

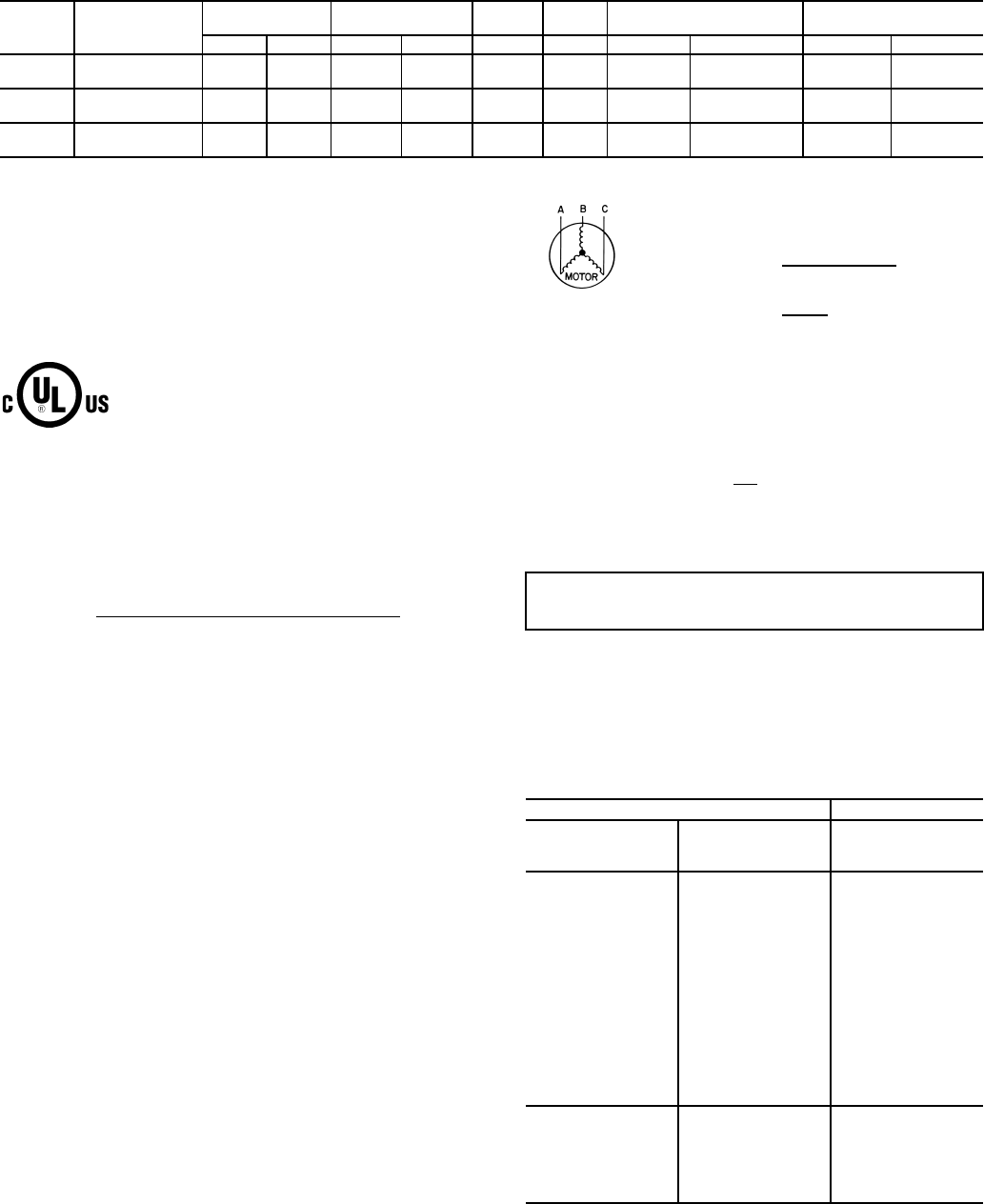

Table 2 — Electrical Data

LEGEND

*Fuse or HACR circuit breaker.

NOTES:

1. In compliance with NEC requirements (U.S.A. Standard) for

multimotor and combination load equipment (refer to NEC Arti-

cles 430 and 440), the overcurrent protective device for the unit

shall be fuse or HACR breaker.

2.

Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%.

Use the following formula to determine

the percent of voltage imbalance.

% Voltage Imbalance

Example: Supply voltage is 400-3-50.

AB = 393 v

BC = 403 v

AC = 396 v

= 397

Determine maximum deviation from average voltage.

(AB) 397 – 393 = 4 v

(BC) 403 – 397 = 6 v

(AC) 397 – 396 = 1 v

Maximum deviation is 6 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

= 1.5%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

Route thermostat cable or equivalent single leads of colored

wire from thermostat subbase terminals to low-voltage connec-

tions on unit (shown in Fig. 10) as described in Steps 1-4

below.

1. If unit is mounted on roof curb and accessory thru-the-

curb service plate connection is used, route wire through

connection plate.

2. Pass control wires through the hole provided on unit (see

connection D in Connection Sizes table in Fig. 6).

3. Feed wires through the raceway built into the corner post

to the 24-v barrier located on the left side of the control

box. See Fig. 11. The raceway provides the UL-required

(Underwriters’ Laboratories) clearance between high-

and low-voltage wiring.

4. Connect thermostat wires to screw terminals on low-

voltage connection board.

HEAT ANTICIPATOR SETTINGS — Set heat anticipator

settings at .14 amp for the first stage and .20 amp for second-

stage heating, except for 008 low heat. Set both first and sec-

ond stage heat anticipator settings for 008 at .14 amp.

Table 3 — American/European Wire Conversions

LEGEND

UNIT

48TF

NOMINAL

VOLTAGE

(50 Hz)

VOLTAGE

RANGE

COMPR

(ea)

OFM

(ea)

IFM POWER SUPPLY

MINIMUM UNIT

DISCONNECT

Min Max RLA LRA FLA FLA MCA MOCP* FLA LRA

008

400

(3 phase)

360 440 6.4 42.0 0.3 2.6 17.6 20 18 108

012

400

(3 phase)

360 440 8.9 52.0 0.3 2.6 23.2 30 24 128

014

400

(3 phase)

360 440 10.4 73.0 0.7 5.4 29.4 35 31 192

FLA —

Full Load Amps

HACR —

Heating, Air Conditioning and Refrigeration

IFM —

Indoor (Evaporator) Fan Motor

LRA —

Locked Rotor Amps

MCA —

Minimum Circuit Amps

MOCP —

Maximum Overcurrent Protection

NEC —

National Electrical Code (U.S.A.)

OFM —

Outdoor (Condenser) Fan Motor

RLA —

Rated Load Amps

= 100 x

max voltage deviation from average voltage

average voltage

Average Voltage =

393 + 403 + 396

3

=

1192

3

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

6

397

AMERICAN EUROPEAN

Industry

Standard Size

American

Conversion

Size (mm

2

)

Industry

Standard

Size (mm

2

)

18 AWG

0.82 1.0

16 AWG

1.30 1.5

14 AWG

2.08 2.5

12 AWG

3.30 4.0

10 AWG

5.25 6.0

8 AWG

6.36 10.0

6 AWG

13.29 16.0

4 AWG

21.14 25.0

3 AWG

26.65 —

2 AWG

33.61 35.0

1 AWG

42.39 50.0

1/0 AWG

53.49 —

2/0 AWG

67.42 70.0

3/0 AWG

85.00 95.0

4/0 AWG

107.19 120.0

250 kcmil

126.64 150.0

300 kcmil

151.97 —

350 kcmil

177.90 185.0

400 kcmil

202.63 240.0

500 kcmil

253.29 300.0

600 kcmil

303.95 —

AWG —

American Wire Gage

kcmil —

Thousand Circular Mils