ENGLISH

26

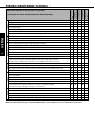

Breather plug front fork

After every 5 hours of use for competitive racing, slacken the breather

plugs [2] a few turns in order to relieve excess pressure from the inside of the

fork. To do this, place the motorcycle on a stand with the front wheel lifted

off the ground. When riding the motorcycle mainly on the road, it will suffice

to have this job performed in the course of the periodical maintenance

service.

Excessive pressure in the interior of the fork can cause leaks in the fork. If

your fork is leaking, it is recommended to open the breather plugs before hav-

ing the seals replaced.

MAINTENANCE WORK ON CHASSIS AND ENGINE »

According to our experience, the damping rate of the compression stage can

remain unchanged. The damping rate of the rebound stage can be reduced

by a few clicks for a softer spring or increased by a few clicks for a harder

spring.

Checking the basic setup of the telescopic fork

The precise riding sag of the telescopic fork cannot be determined for vari-

ous reasons. Similar to the shock absorber, smaller deviations in your weight

can be compensated by adjusting the spring preload. However, if your tele-

scopic fork bumps frequently (hard end stop during compression), you should

install harder fork springs to avoid damaging the telescopic fork and frame.

Your KTM dealer will be happy to offer advice.

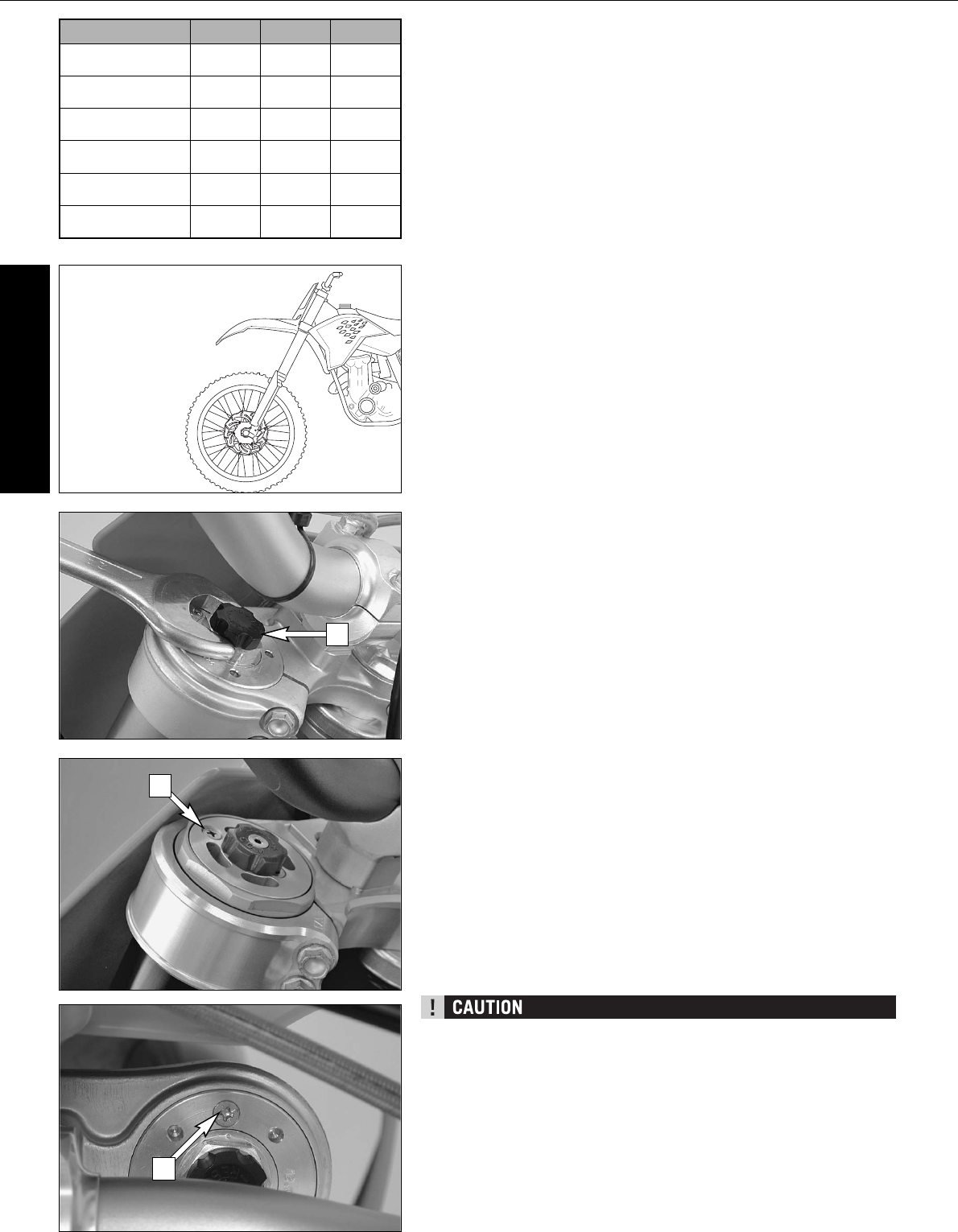

Changing the spring preload on the telescopic fork (XC-W, EXC,

EXC Six Days, EXC-E, EXC-E Six Days)

The telescopic forks for these models are equipped with a preload adjuster.

You can easily adjust the spring preload by 10 mm by turning the adjusting

screw [1].

Turning in a clockwise direction will increase the prestress, turning in a coun-

terclockwise direction will decrease the prestress.

Changing the spring preload will not affect the rebound damping adjustment.

Generally, if the spring preload is higher, the rebound damping should also

be set higher.

STANDARD SETTING:

Turn the adjusting screw all the way to the stop in a counterclockwise direc-

tion and 2 turns in a clockwise direction.

TYPE SOFTER

STANDARD

HARDER

12187D02

63-250

66-250

69-250

12187D04

66-250

69-250

72-250

12187D27 60-250

63-250

66-250

12187D28 60-250

63-250

66-250

12187D33 63-250

66-250

69-250

12187D34 66-250

69-250

72-250

2

1

2