13

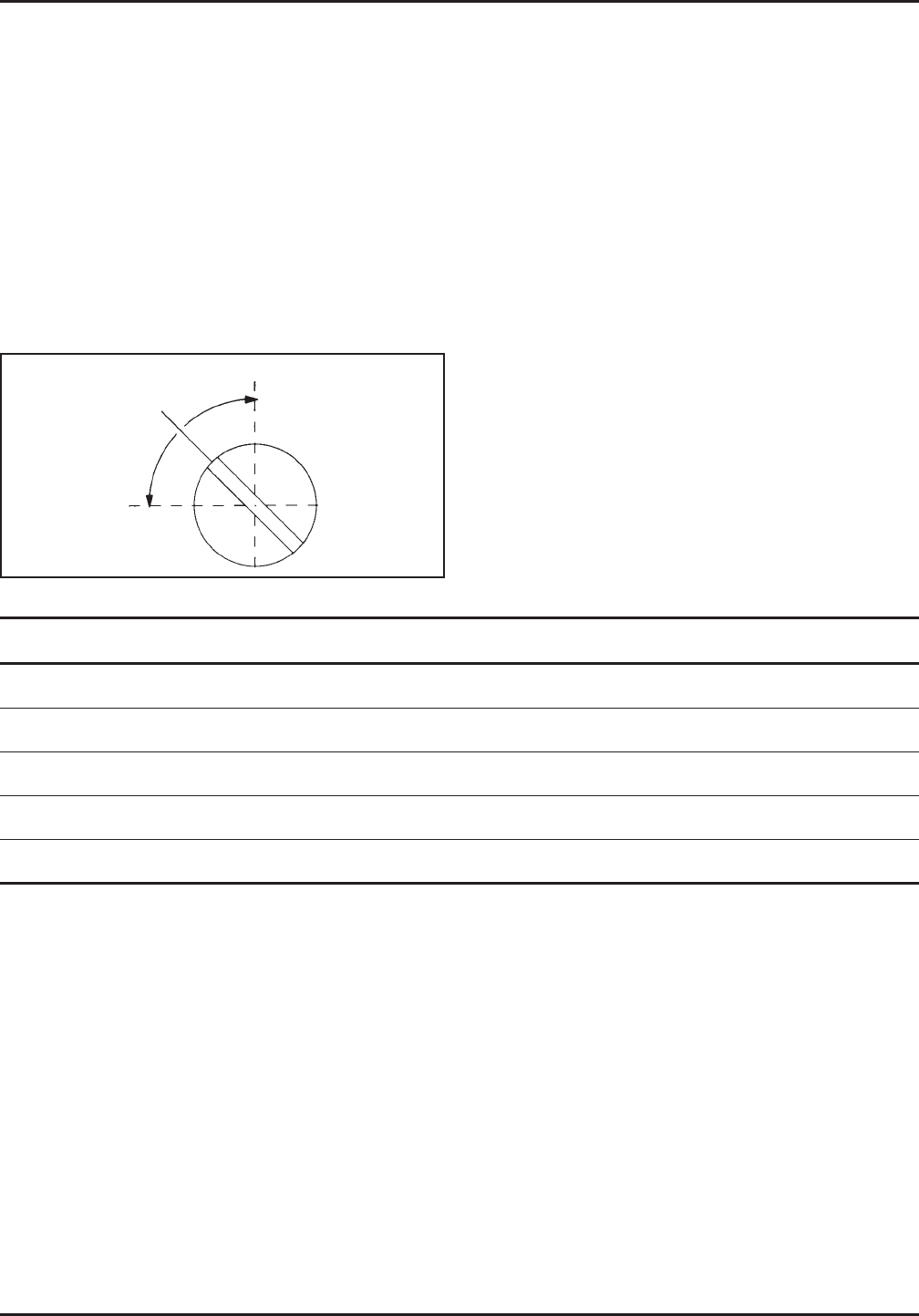

2. Low Idle Fuel Needle Setting: Place the throttle

into the idle or slow position.

Turn the low idle fuel adjusting needle out

(counterclockwise) from the preliminary setting

until engine speed decreases (rich). Note the

position of the needle.

Now turn the adjusting needle in (clockwise). The

engine speed may increase, then it will decrease

as the needle is turned in (lean). Note the position

of the needle.

Set the adjusting needle midway between the

rich and lean settings. See Figure 15.

Storage

If the engine will be out of service for two months or

more, use the following storage procedure:

1. Clean the exterior surfaces of the engine.

2. Change the oil and filter while the engine is still

warm from operation. See Change Oil and Filter

on page 9.

3. The fuel system must be completely emptied, or

the gasoline must be treated with a stabilizer to

prevent deterioration. If you choose to use a

stabilizer, follow the manufacturers

recommendations, and add the correct amount

for the capacity of the fuel system. Fill the fuel

tank with clean, fresh gasoline. Run the engine for

2-3 minutes to get stabilized fuel into the

carburetor.

To empty the system, run the engine until the

tank and system are empty.

4. Due to the deep recess around the spark plug,

blow out the cavity with compressed air. Remove

the spark plug. The spark plug is most accessible

when the blower housing is removed for

cleaning.

Add one tablespoon of engine oil into the spark

plug hole. Install the plug, but do not connect the

plug lead. Crank the engine two or three

revolutions. Connect the plug lead.

5. Reinstall the blower housing, if removed

previously, and torque the blower housing

screws to 7.5 N·m (65 in. lb.).

6. Store the engine in a clean, dry place.

3. Low Idle Speed Setting: Place the throttle control

into the idle or slow position. Set the low idle

speed to 1500 RPM* (± 75 RPM) by turning the

low idle speed adjusting screw in or out. Check

the speed using a tachometer.

*NOTE: The actual low idle speed depends on the

application – refer to equipment

manufacturer’s recommendations. The

recommended low idle speed for basic

engines is 1500 RPM. To ensure best

results when setting the low idle fuel

needle, the low idle speed must not

exceed 1500 RPM (± 75 RPM).

Troubleshooting

When troubles occur, be sure to check the simple

causes which, at first, may seem too obvious to be

considered. For example, a starting problem could be

caused by an empty fuel tank. Some common causes of

engine troubles are listed in the following table.

Do not attempt to service or replace major engine

components, or any items that require special timing

or adjustment procedures. Have your Kohler Engine

Service Dealer do this work.

Possible Cause No Improper Dirt In Dirty Incorrect Engine Dirty Air Faulty

Problem Fuel Fuel Fuel Line Grass Screen Oil Level Overloaded Cleaner Spark Plug

Will Not Start ••• ••••

Hard Starting ••• ••••

Stops Suddenly • •••••

Lacks Power •••••••

Operates Erratically ••• • ••

Knocks or Pings •• • •

Skips or Misfires ••• ••

Backfires ••••

Overheats •••••

High Fuel Consumption •••

Figure 15. Optimum Low Idle Fuel Setting.

Lean

Rich

Adjust to

Midpoint