7-10 ENGINE BOTTOM END/TRANSMISSION

Crankshaft, Connecting Rod

Crankshaft Removal

•

Split the crankcase (see Crankcase Splitting).

•

Remove the transmission shafts (see Transmission Shaft

Removal).

•

Using a press, remove the crankshaft from the right

crankcase.

○

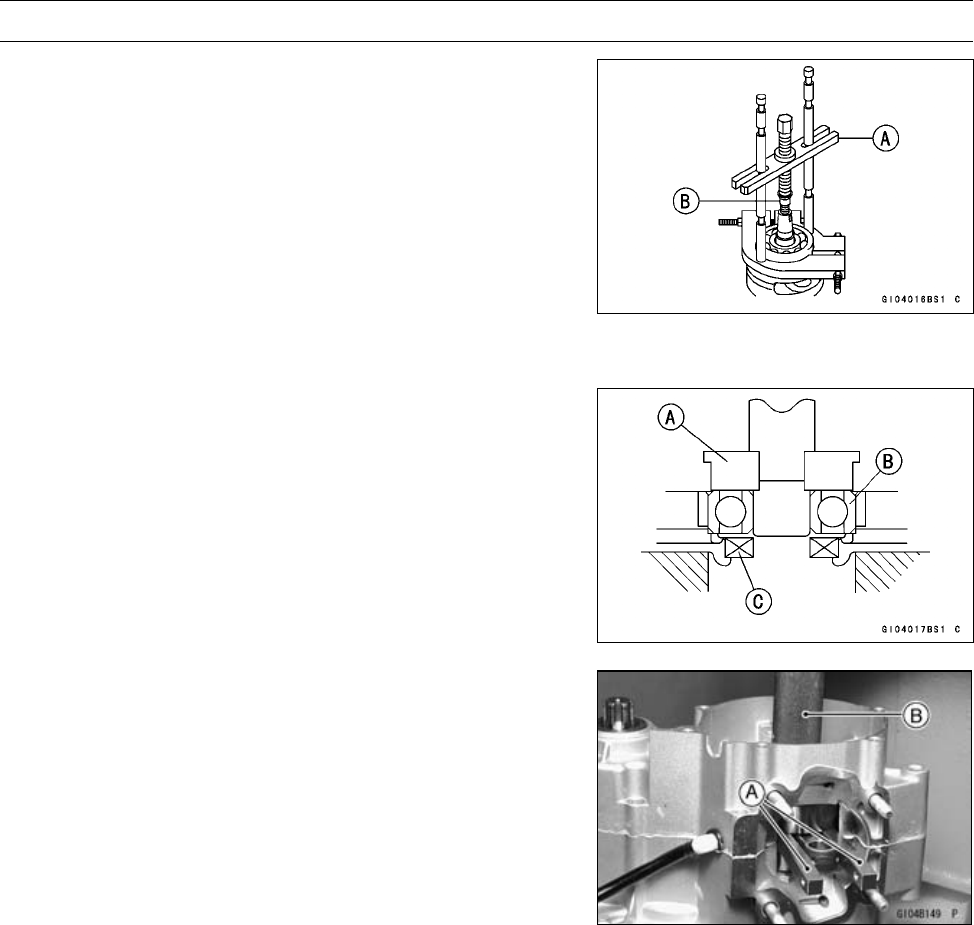

If the bearings stay on the crankshaft when splitting the

crankcase or removing the crankshaft from the right

crankcase, remove the bearings from the crankshaft with

a bearing puller [A] and adapter [B].

Special Tools - Bearing Puller: 57001-158

Bearing Puller Adapter: 57001-136

Crankshaft Installation

•

When installing the crankshaft bearings [B], apply high

temperature grease to the outer sides of the bearings,

and then press them into the crankcase using the bearing

driver [A] until the bearing bottoms against the step.

○

Position the crankcase half so that the main bearing hous-

ing is seated on a suitable press fixture.

○

Install the crankshaft bearing so that the sealed side in (to

the oil seal [C] side).

Special Tool - Bearing Driver Set: 57001-1129

•

Insert the crankshaft jig [A] between the crankshaft fly-

wheels opposite the connecting rod big end to protect

flywheel alignment as shown, and using a suitable tool

[B] on the left crankcase to press around the hole for the

crankshaft.

○

When pressing, position the jig in the crankcase opening

so the jig does not hit the crankcase.

Special Tool - Crankshaft Jig: 57001-1439

•

Apply 2-stroke oil to the connecting rod big end bearing.

Crankshaft Disassembly

Since assembly of the crankshaft demands exacting tol-

erances, the disassembly and reassembly of the crankshaft

can only be done by a shop having the necessary tools and

equipment.

•

If it should be necessary to disassemble the crankshaft,

use a press to remove the crankpin.

Crankshaft Assembly

Since the assembly of the crankshaft demands exacting

tolerances, the disassembly and reassembly of the crank-

shaft can only be done by a shop having the necessary tools

and equipment.

•

Reassemble the crankshaft according to the standard tol-

erances in Specifications.

○

Connecting rod bend, twist

○

Connecting rod big end radial clearance.

○

Cold-fitting tolerance between crankpin and flywheels.

○

Side clearance between the connecting rod big end and

one of flywheels.

○

Crankshaft runout.