Engine AJ-V8/5HP24

9

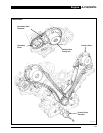

Connecting Rods and Pistons

The connecting rods are manufactured in sinter

forged steel. The bearing caps are produced by

fracturing the opposing sides of the connecting rod at

the bearing horizontal center-line. As well as being

easier to manufacture, when re-assembled the

fractured surfaces interlock to form a strong

seamless joint. The cylinder position is etched on

adjoining sides of the joint to identify matching

connecting rods and bearing caps. The connecting

rod bearings are lead/bronze split plain bearings.

The pistons are of the open ended skirt design with

flat upper surfaces to reduce heat absorbtion. Three

piston rings, two compression and one oil control, are

installed on each piston. Each piston is installed on a

wrist pin located in a lead/bronze bushing in the

connecting rod.

Sump

The sump consists of an aluminum alloy structural

sump bolted to the bedplate, and a pressed steel oil

pan bolted to the structural sump. A windage tray

attached to the top of the structural sump isolates

the oil pan from the disturbed air produced by the

rotation of the crankshaft, to prevent oil aeration and

improve oil drainage. A rubber plug at the rear of the

structural sump seals the port that provides access to

the torque converter securing bolts. The engine oil

drain plug is located at the front right corner of the oil

pan.

A silicon rubber in-groove gasket seals the joint

between the oil pan and the structural sump; a bead

of sealant seals the joint between the structural

sump and the bedplate.

CONNECTING ROD AND PISTON

303-014

SEALANT TRACK ON STRUCTURAL SUMP

303-021