8

XL-FW247-01

1

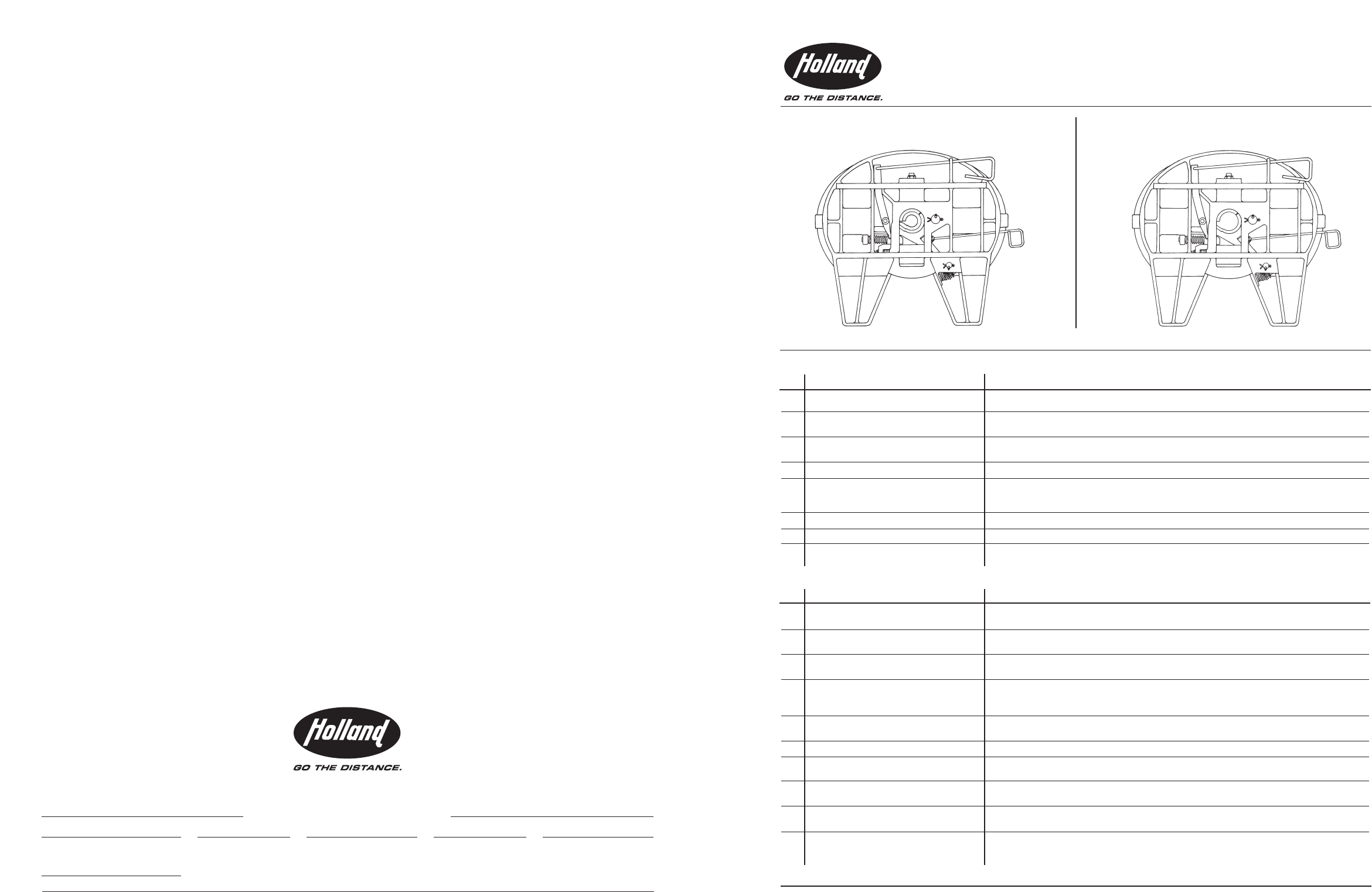

XA-2081-DA XA-2081-OA

2” SAE Kingpin (Rebuild Kit RK-65012) 3

1

⁄2” SAE Kingpin (Rebuild Kit RK-65013)

Troubleshooting and Rebuilding Procedures for

XA-2081 SERIES Fifth Wheel Top Plates

TROUBLE SHOOTING HINTS

Fifth Wheel is Hard to Hook Up to Trailer:

✔ POSSIBLE CAUSE REMEDY

■■

The trailer may be too high; the kingpin Lower the trailer landing gear.

is not entering the locks properly.

■■

Locks are closed. Pull the secondary and primary release handles to the unlocked position and pry the

hinged lock open.

■■

Accumulated rust or grime Spray a light lubricant or diesel fuel on all moving parts including the release

interfering with the lock operation. handle and operate several times.

■■

The locks are adjusted too tightly. Check lock adjustments in accordance with the procedure in this manual.

■■

Bent release handle or kingpin or Check the kingpin with a Holland TF-0110 Kingpin Gage and bolster plate with a

damaged bolster plate may be 48˝ straightedge. Repair/replace as required. The kingpin can be inspected in

interfering with lock movement. accordance with SAE J2228.

■■

The locks may be damaged. Inspect and replace if required following the procedures in this manual.

■■

The fifth wheel may need rebuilding. Follow the procedures contained in this manual using the appropriate rebuilding kit.

■■

Using lube plate with wrong kingpin See Holland Service Bulletin XL-SB4.

length.

Fifth Wheel is Hard to Unhook from Trailer:

✔ POSSIBLE CAUSE REMEDY

■■

The secondary lock is not released. Pull the secondary lock release handle and lift up to engage the handle lug with the

top plate casting.

■■

The tractor may be putting pressure Back the tractor into the trailer to relieve the pressure and lock the tractor brakes

against locks. before pulling the release handle.

■■

Rust or grime on the locking Spray a light lubricant or diesel fuel on all moving parts including the release handle

mechanism. and operate several times.

■■

Bent kingpin or damaged bolster Check the kingpin with a Holland TF-0110 Kingpin Gage and bolster plate with a

plate. 48˝ straightedge. Repair/replace as required. The kingpin can be inspected in

accordance with SAE J2228.

■■

Fifth wheel locks may be adjusted Check the lock adjustment in accordance with procedures in this manual.

too tight.

■■

The release handle will not stay out. Pull the release handle out and up, then release.

■■

The release handle will not stay out; Replace release handle.

pops off lug.

■■

The release handle must be held out Build up release handle lug to hold out further or replace release lever (15) or release

when uncoupling. handle (16).

■■

Using lube plate with wrong kingpin See Holland Service Bulletin XL-SB4.

length.

■■

Long plunger. Pull the release handle to the fully extended position and hold it while someone else

attempts to uncouple. If the locks do not open under this condition, close the swinging lock

partially and grind 1/16˝ of the tip of the swinging lock. Round off after grinding.

NOTE: After the fifth wheel is unlocked and moves freely from the kingpin, it is normal for the release handle to return to the “in” position.

Copyright © September 2002 • The Holland Group, Inc.

HOLLAND USA, INC.

1950 Industrial Blvd. • P.O. Box 425 • Muskegon, MI 49443-0425

Phone 888-396-6501 • Fax 800-356-3929

www.thehollandgroupinc.com

Holland USA, Inc. Facilities:

Denmark, SC Warrenton, MO

Dumas, AR Whitehouse Station, NJ

Holland, MI Wylie, TX

Muskegon, MI

Ph: 888-396-6501 Fax: 800-356-3929

Holland International, Inc.

Holland, MI

Phone: 616-396-6501

Fax: 616-396-1511

Holland Equipment, Ltd.

Norwich, Ontario • Canada

Phone: 519-863-3414

Fax: 519-863-2398

Holland Hitch Western, Ltd.

Surrey, British Columbia • Canada

Phone: 604-574-7491

Fax: 604-574-0244

Holland Hitch of Canada, Ltd.

Woodstock, Ontario • Canada

Phone: 519-537-3494

Fax: 800-565-7753