Page 16 For technical questions, please call 1-800-520-0882. Vertical Engine

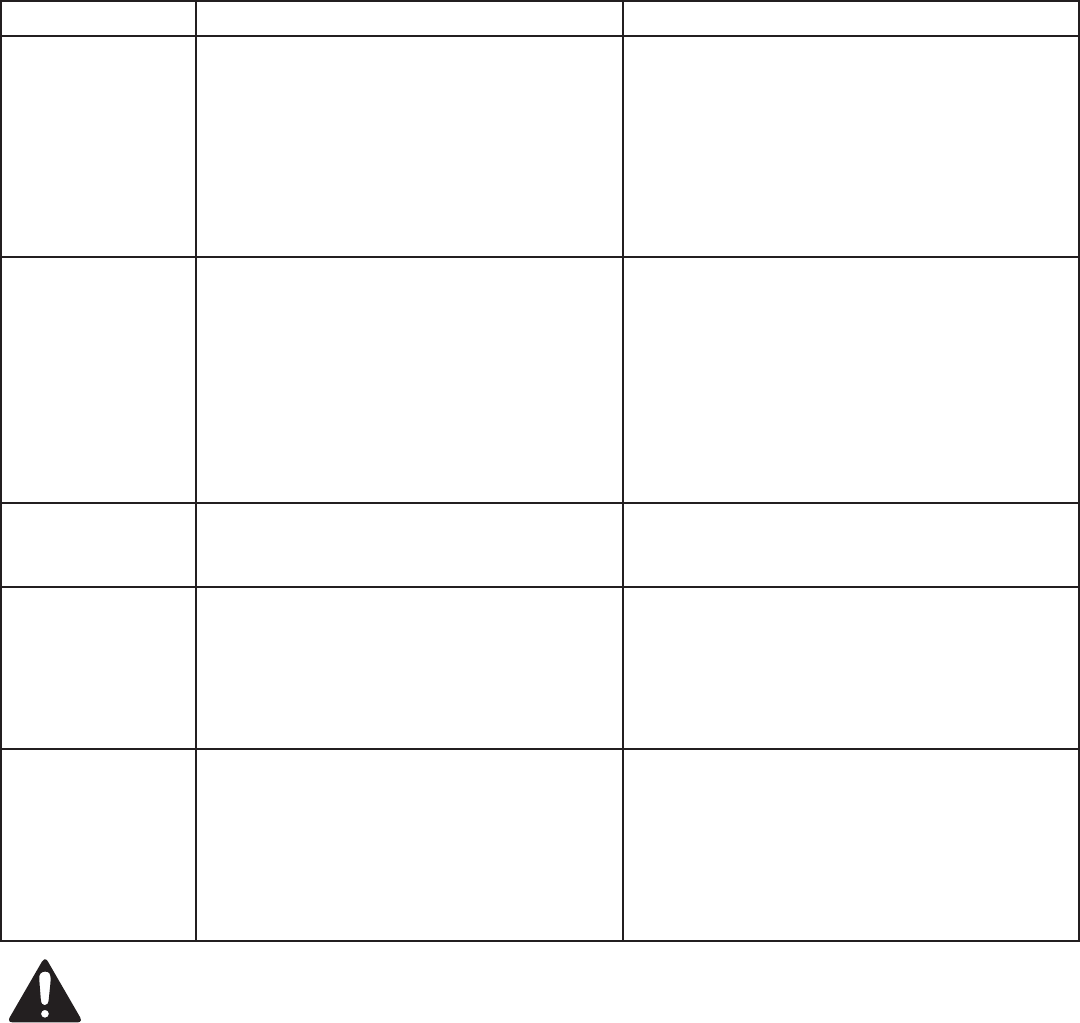

Problem Possible Causes Probable Solutions

Enginemisres 1. Spark plug cap loose.

2. Incorrect spark plug gap or

damaged spark plug.

3. Defective spark plug cap.

4. Old or low quality gasoline.

5. Incorrect compression.

1. Check wire connections.

2. Re-gap or replace spark plug.

3. Replace spark plug cap.

4. Use only fresh 87+ octane unleaded gasoline.

5. Diagnose and repair compression.

(Use Engine will not start:

COMPRESSION RELATED section.)

Engine stops

suddenly

1. Low oil shutdown.

2. Fuel tank empty or full of impure

or low quality gasoline.

3. Defective fuel tank cap creating

vacuum,preventingproperfuelow.

4. Faulty magneto.

5. Disconnected or improperly

connected spark plug cap.

1. Fill engine oil to proper level. Check

engine oil before EVERY use.

2. Fill fuel tank with fresh 87+

octane unleaded gasoline.

3. Test/replace fuel tank cap.

4. Havequaliedtechnicianservicemagneto.

5. Secure spark plug cap.

Engine stops when

under heavy load

1. Dirtyairlter

2. Engine running cold.

1. Clean or replace element.

2. Allow engine to warm up prior

to operating equipment.

Engine knocks 1. Old or low quality gasoline.

2. Engine overloaded.

3. Incorrect spark timing, deposit

buildup, worn engine, or other

mechanical problems.

1. Fill fuel tank with fresh 87+

octane unleaded gasoline.

2. Do not exceed equipment’s load rating.

3. Havequaliedtechniciandiagnose

and service engine.

Enginebackres 1. Impure or low quality gasoline.

2. Engine too cold.

3. Intake valve stuck or overheated engine.

4. Incorrect timing.

1. Fill fuel tank with fresh 87+

octane unleaded gasoline.

2. Use cold weather fuel and oil

additivestopreventbackring.

3. Havequaliedtechniciandiagnose

and service engine.

4. Check engine timing.

Follow all safety precautions whenever diagnosing or servicing the equipment or engine.