20

Step 9 — Adjust Evaporator-Fan Speed —

Ad-

just evaporator-fan speed to meet jobsite requirement.

Table 6 shows motor performance. Tables 7 and 8 show fan

rpm at motor pulley settings, Table 9 shows motor efficiencies

and Tables 10 and 11 give accessory static pressure drops. Re-

fer to Tables 12-23 to determine fan speed settings. Fan motor

pulleys are factory set for speed shown in Table 1A or 1B.

To change fan speed:

1. Shut off unit power supply and install lockout tag.

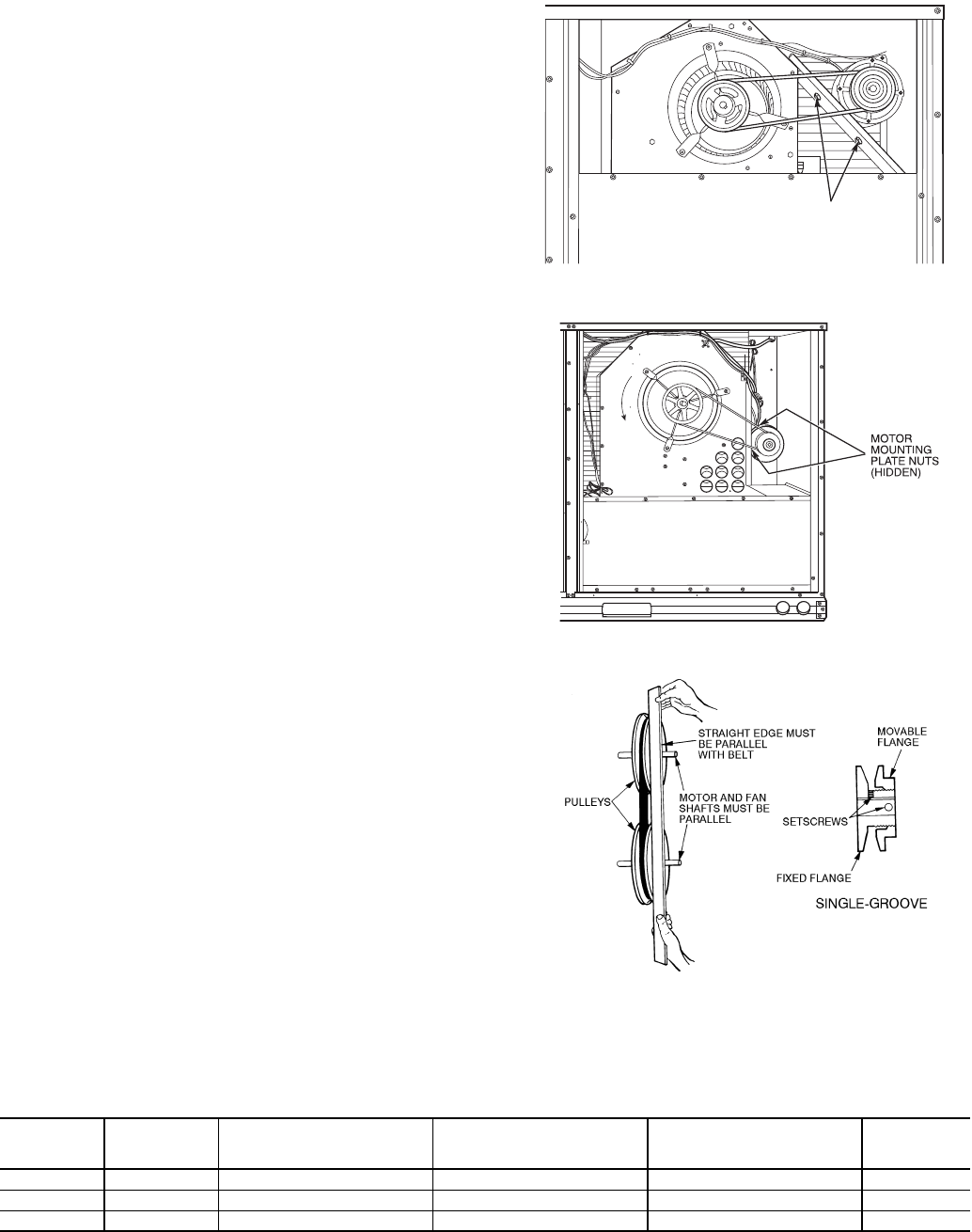

2. Loosen belt by loosening fan motor mounting plate nuts

(see Fig. 42 and 43).

3. Loosen movable pulley flange setscrew (see Fig. 44).

4. Screw movable flange toward fixed flange to increase fan

speed and away from fixed flange to decrease fan speed.

Increasing fan speed increases load on motor. Do not ex-

ceed maximum speed specified in Table 1A or 1B.

5. Set movable flange at nearest flat of pulley hub and tight-

en setscrew (see Table 1A or 1B for speed change for

each full turn of pulley flange).

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from

mounting plate.

To adjust belt tension (see Fig. 42 and 43):

1. Loosen fan motor mounting nuts.

2. Size 008 — Slide motor mounting plate away from fan

scroll for proper belt tension (13 mm [

1

/

2

-in.] deflection

with 3.6 to 4.5 kg [8 to 10 lbs] of force) and tighten

mounting nuts. See Fig. 42.

Sizes 012,014 — Slide motor mounting plate downward

to tighten belt tension (13 mm [

1

/

2

-in.] deflection with 2.3

to 4.5 kg [5 to 10 lbs] of force) and tighten mounting nuts.

See Fig. 43.

3. Adjust bolt and nut on mounting plate to secure motor in

fixed position. See Fig. 44.

Realign fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from

mounting plate.

Table 6 — Evaporator-Fan Motor Performance

LEGEND *Extensive motor and electrical testing on these units ensures that

the full range of the motors can be utilized with confidence. Using

your fan motors up to the ratings shown in this table will not result in

nuisance tripping or premature motor failure. Unit warranty will not

be affected.

UNIT

48TF

UNIT RATED

VOLTAGE

MAXIMUM ACCEPTABLE

CONTINUOUS

BkW*

MAXIMUM ACCEPTABLE

CONTINUOUS

BHP*

MAXIMUM ACCEPTABLE

OPERATING

WATTS

MAXIMUM

AMP DRAW

008

400 2.76 2.90 2615 3.6

012

400 2.76 3.70 3313 5.0

014

400 2.76 3.70 3313 5.0

BHP —

Brake Horsepower

BkW —

kW x Motor Efficiency

MOTOR MOUNTING

PLATE NUTS

Fig. 42 — Typical Belt-Drive Motor Mounting

for Size 008

Fig. 43 — Typical Belt-Drive Motor Mounting

for Sizes 012,014

Fig. 44 — Evaporator-Fan Pulley Adjustment